Mark72233

Ensign

- Joined

- Jul 11, 2014

- Messages

- 926

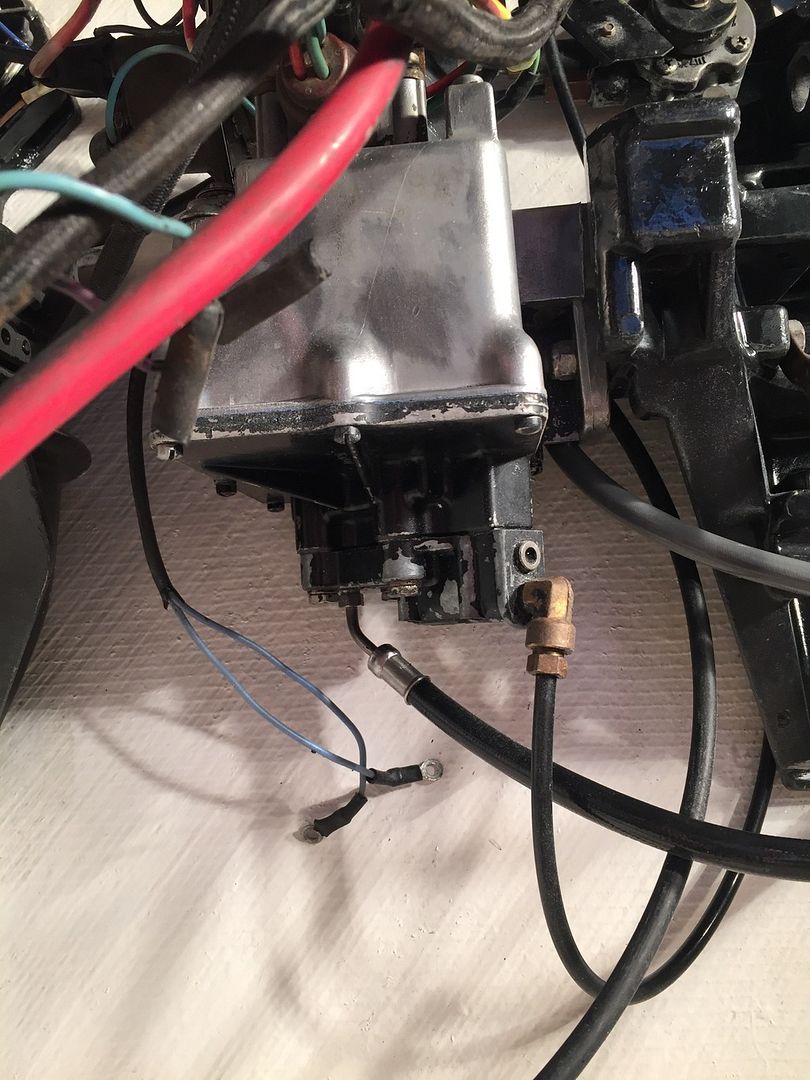

Thanks for the diagram AllDodge. That was the first thing I check and it was connected correctly it is the rams. Before I put them on I tested the 7 rams that I have and found the best 4 but when I say best I should have still taken them apart and rebuilt them. They are tight and sticking when I try to pull them in and out and after this one exploded I took it apart and it was nasty inside of it. Lessoned learned don't try and use rams unless they go in and out very smooth by hand.