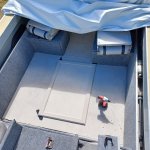

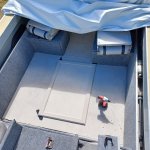

Much slower progress this year. This weekend I did manage to get my rear seat covers and drawer fronts carpeted, now awaiting hinges. Got the floor storage lid made as well.

I think it will look good when all done, but I definitely notice some flaws in my work, such as not so 90 degree angles in the rear structure.

Figured I'd start a list of things that I'd do differently next time. Keeping in mind that I started this boat under a different budget that has since been relaxed. Maybe it will help future builds in their planning.

-plywood and sealant. If properly sealed, I don't see CDX as being an issue, but in the future I would use epoxy for sealer rather than a mix of BLO and spar urethane. I have noticed some mildew growth on some of the BLO, though this may get mitigated in the future with better ventilation and covering.

I do like my painted canvas floors and from other places I have seen this done I think it will hold up well. The question is if the underside will as well. Also the carpeted plywood only sealed with BLO.

-my transom was laminated by 4 pieces of CDX, this ended up being a tighter fit than 2 layers of 3/4", causing some scraping of the sealing layer and smashing/cracking where I had to use a mallet. This was a case of the previously smaller budget.

-purchase a quality cover as soon as you buy the boat. For one, I lost a weekend or two at the start trying to figure out how to melt ice out of my boat. Second, I was slow to cover this last fall and rainwater got in which caused most mildew issues.

-if you are going to remodel the splashwell, either make it all out of plywood and then fiberglass the well, or make sure you have proper tools for the metal forming. I think this partly contributed to my not so 90 degree angles in the back structure. It also made a lot more work trying to match an uneven metal form.

-windshield, not really something that I am currently thinking I wish I had done differently since it will be an easy replacement, and right now it's primarily time constraints keeping me from doing so. I do want to make my own custom windshield in the future though. A more robust frame and also taller.

-boat trailer. Again, easy to replace later, but I should have held out for something better rather than putting time (cutting/grinding/welding) into remodeling the current trailer. I likely would have broken even and been time ahead just making my own from scratch even. I'm probably an anomaly for reworking a trailer to this extent, though.

Anyway, the boat will still look good when I'm done, at least from 10 ft. Hopefully more progress next weekend.