Sharpie223

Petty Officer 2nd Class

- Joined

- May 24, 2021

- Messages

- 183

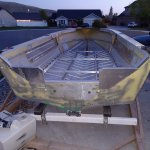

Weekend update. Got the remaining two transom ears in place. Sanded, sawed, and butchered the wood until it was flush with aluminum, and then coated the raw edges with gluvit. Also got angle crossbars installed at the joint location of each deck board, this should stiffen the floor better than the straps the factory used.

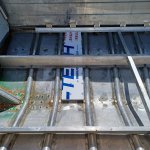

The previous owner had an aluminum plate box welded onto the transom trim for a kicker motor mount. I thought this was a bit overkill but decided, sawed in half, it would make a good support for a rear deck. So this got added on with some pc-7 in-between. I would have preferred 5200 for this, but decided to use what I have, it's above the water line and plenty fixable later if need be.

Finally, added my splashwell drain holes. Aluminum tubes for liner, epoxy coated between metal and wood, flared on the inside. Then the transom metal to liner contact has been puttied together. The inside will be covered in flashing after this, with the flashing flared into the liners, the goal being that water can't touch wood.

The previous owner had an aluminum plate box welded onto the transom trim for a kicker motor mount. I thought this was a bit overkill but decided, sawed in half, it would make a good support for a rear deck. So this got added on with some pc-7 in-between. I would have preferred 5200 for this, but decided to use what I have, it's above the water line and plenty fixable later if need be.

Finally, added my splashwell drain holes. Aluminum tubes for liner, epoxy coated between metal and wood, flared on the inside. Then the transom metal to liner contact has been puttied together. The inside will be covered in flashing after this, with the flashing flared into the liners, the goal being that water can't touch wood.