Moserkr

Chief Officer + Starmada Splash Of The Year 2021

- Joined

- Nov 23, 2020

- Messages

- 883

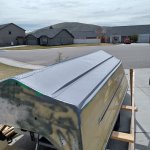

Mine had a big crack that I jb welded, sanded, then painted over…. But the u-bolt for the trailer winch hook up would be a better point to lift from. Nose caps are cast aluminum and pretty weak, and not attached well.An original nose cap and you drilled a hole through it!?!?!?!?!?! lol

Good progress

SHSU

Wish mine had the OG side rub rail. Not sure which PO(s) took that off lol

Once the paint stripping is done, it gets a lot more fun. That part damn near killed me.