This weekend I got the solid rivets securing the tabs on. Some tails ended up smooshed to one side, but they are tight, so I think they should be okay. They also all got a good dose of 5200.

Deck boards got a slathering of spar urethane across the bottom. The two largest also got a coating of oil based primer, just for good measure. The front boards will get the same, just ran out of room while coating my transom with spar. The transom was flush routed to knock down any high spots. The edges doused in penetrating epoxy, and then varnished.

Would it be cheaper to just buy laminating epoxy to seal the wood? Probably, or just a nominal amount more. But so far I had everything on hand already other than the spar varnish, and it's nice to finally use those things stored away because "this might be useful someday..."

Next up will be removing the last remnants of silicone that the previous owner globbed on, then leak checking the rivets, buzzing any that seem to allow fluid through.

Then it will be closed end riveting the ends of the tabs down.

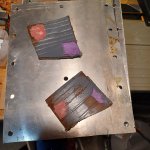

Deck tops will have canvas glued to the top, and then stapled underneath the edges, then painted. This makes a nice floor and protects the wood surprisingly well.

After that, I am not sure. The weather is going to cool again to a point where epoxies will take too long to cure, so will 5200. I don't mind heat curing some epoxies in small sections but don't want to do a whole boat that way. So I will probably begin work on cutting new dash panels, maybe triming down and reshaping the splashwell, stockpile materials, and otherwise the project will then be on pause until warmer weather comes.