Badfish95

Petty Officer 2nd Class

- Joined

- Jun 30, 2012

- Messages

- 118

Re: 1995 Crownline 202 BR Deck Restoration

More foaming photos. Hopefully tomorrow I can get out there and plug the holes. I have about a gallon and a half of resin left from my original 15 gallons and another 5 gallons of resin coming on Monday. I saw in another thread that boat building follows the rule of PI.... Take what you thought it was going to cost and multiply that by PI 3.141.... Originally budgeted $1,200-$1,500 so the math is working out quite nicely :facepalm:

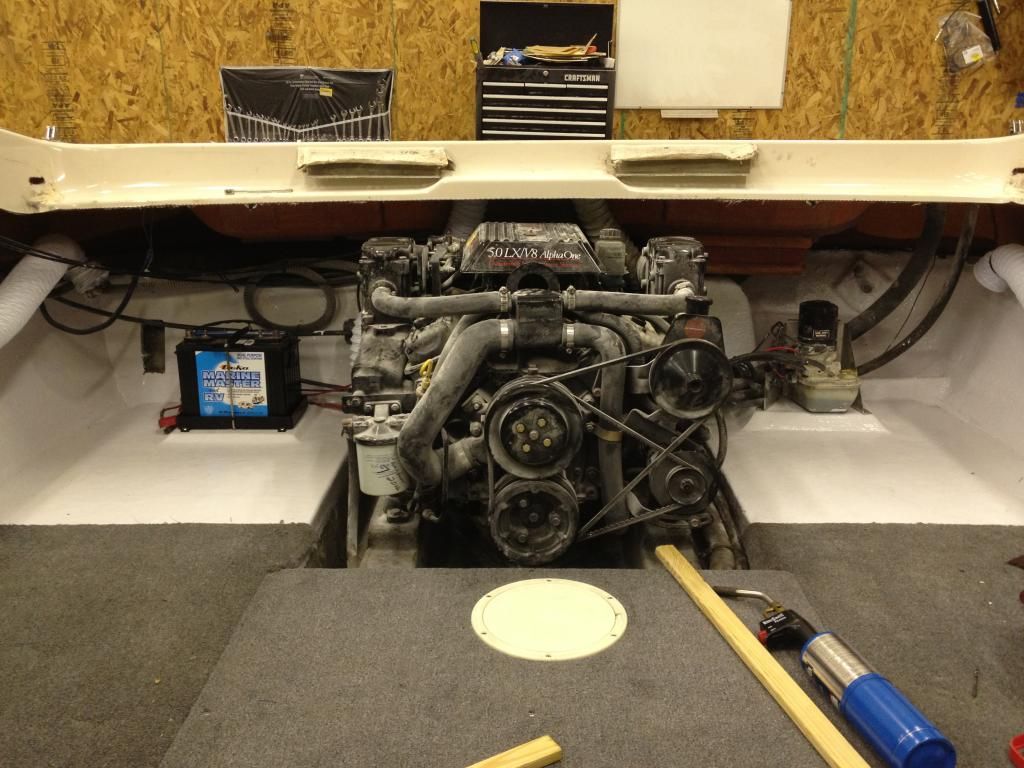

I already bought the carpet and still plan on using it. My new plan is to only carpet the areas that are open to the air. I will carpet from the bilge to the bow. The other areas will likely get the Rustoleum industrial paint job that WOG has outlined. That way, when wet lifejackets get stowed under the rear hatch, the carpet wont trap the moisture against the deck. The rear sundeck supports were originally screwed into the deck creating a place for water intrusion. I may not carpet those like they were originally. They are already coated with spar urethane. I may scuff them and paint them the same color as the rear bilge, deck area. This way I can apply silicone to the to the screw heads/removable areas to hopefully prevent water intrusion. If I ever need to remove the rear sun deck framing to get at the engine, I can just reapply the silicone.

More foaming photos. Hopefully tomorrow I can get out there and plug the holes. I have about a gallon and a half of resin left from my original 15 gallons and another 5 gallons of resin coming on Monday. I saw in another thread that boat building follows the rule of PI.... Take what you thought it was going to cost and multiply that by PI 3.141.... Originally budgeted $1,200-$1,500 so the math is working out quite nicely :facepalm:

I already bought the carpet and still plan on using it. My new plan is to only carpet the areas that are open to the air. I will carpet from the bilge to the bow. The other areas will likely get the Rustoleum industrial paint job that WOG has outlined. That way, when wet lifejackets get stowed under the rear hatch, the carpet wont trap the moisture against the deck. The rear sundeck supports were originally screwed into the deck creating a place for water intrusion. I may not carpet those like they were originally. They are already coated with spar urethane. I may scuff them and paint them the same color as the rear bilge, deck area. This way I can apply silicone to the to the screw heads/removable areas to hopefully prevent water intrusion. If I ever need to remove the rear sun deck framing to get at the engine, I can just reapply the silicone.