Re: 1994 Chaparral 230 rebuild thread

great info!!!!!!

thanks

Wood flour is not recommended due to the fact that polyester is a bit hygroscopic, meaning it can allow some water absorption, albeit very minute. Wood flour just adds to the problem. Thus you don't want to use it. Bondo uses talc as it's filler for its products and it's almost as bad as wood flour and that's why it's not used for water immersed products. Cabosil and glass bubbles will not absorb water and thus are good products for thickening polyester resin. Epoxy is far less hygroscopic and you CAN use wood flour with it.

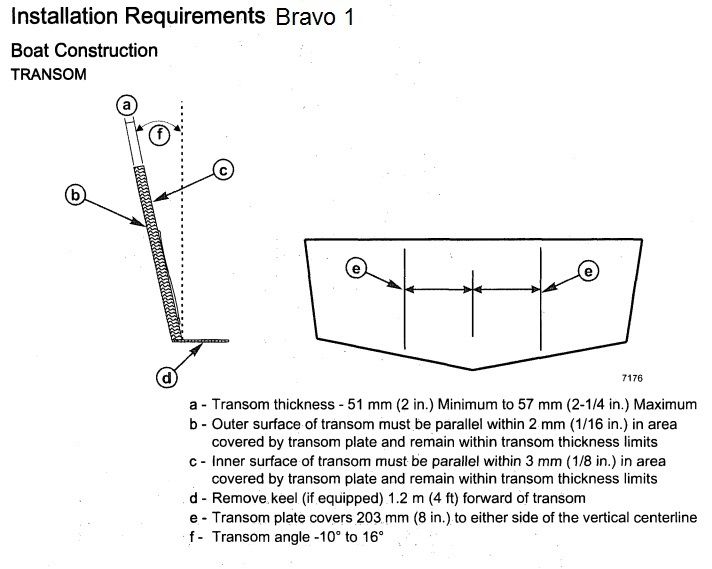

Here's the specs on your transom...

great info!!!!!!

thanks