- Joined

- Jul 18, 2011

- Messages

- 18,959

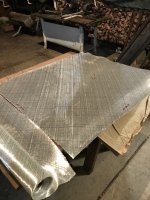

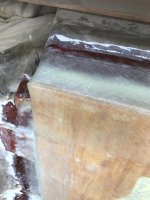

A judgement call in the fuel tank as to if it can be saved. Check to see if there is a certification label with the material and thickness. I would not go with any pits that are deeper than 1/3 the thickness. Also see if you can get a glimpse inside the tank for any internal corrosion/pits. A decent way to purge the fumes would be to store the tank inverted with the sender hole and fill fitting open to the air. Still caution should be used in handling the tank and avoiding sparks.

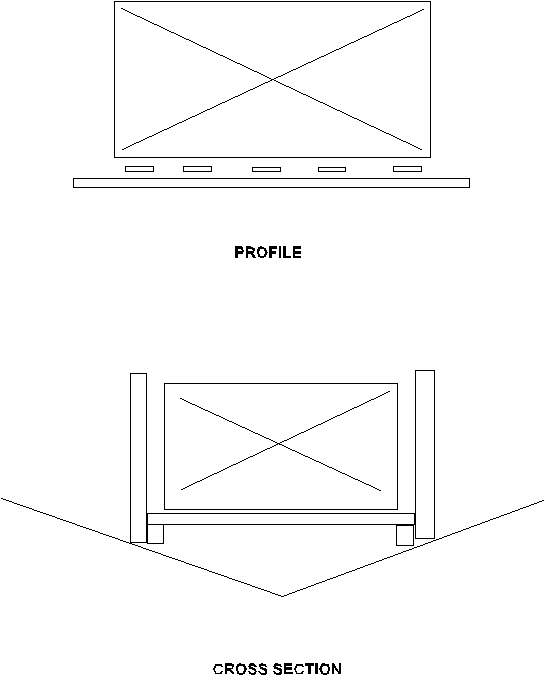

If you do need a new tank, a local welding shop can make one from the dimensions of the original. (BTDT).

If you get rid of the thru-hull fitting, I'd do a glass over of the area, inside and out. If you do a Port-a-Pot, get one with a pump-out connection, so you can pump out if desired vs. having to do a sanitary engineering haul when it needs to be emptied.

If you do need a new tank, a local welding shop can make one from the dimensions of the original. (BTDT).

If you get rid of the thru-hull fitting, I'd do a glass over of the area, inside and out. If you do a Port-a-Pot, get one with a pump-out connection, so you can pump out if desired vs. having to do a sanitary engineering haul when it needs to be emptied.