A few days late on this update, but I continue to make slow steady progress, especially because I am off work this week. Spending a lot of time on family activities, but I have been getting a few hours each morning on the boat. At this pace I will win the award for slowest rebuild!

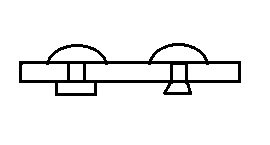

I spent the last 10 days grinding the paint and rust off the trailer frame with an angle grinder. Progress was very slow with the wire brush, the paint was almost gummy and incredibly thick. I finally ended up getting one of the 40gr paint stripper pads for the grinder and that went through it like nothing, but the pads wore out after only one of the long frame pieces and at $16 a pad I'm glad I only needed 2! After all the paint was stripped I wiped the pieces down with mineral spirits and sprayed with Tremclad red oxide primer, and yesterday I rolled on the first coat of white (I ended up swapping the flat white for a gloss white) with a foam roller. The first coat was not a great job, a few bubbles and not fantastic coverage, so I'll give it a light sand before coat 2. My winch tower (pic 1 and 2) is quite a bit more rusted then the rest of the frame, do you guys think I should try and have that bottom plate cut off and a new one welded on? I would have to find a shop for this, as my buddy with a welder is not confident enough to do a structural piece, although he will be taking a stab at fixing those cuts in the trailer fender. I still have to clean up the axle and springs to get it ready for black paint, but they are not horribly rusty so that should go much quicker.

I've also been puttering here and there with vinegar bathing, wire wheeling, and oiling the trailer bolts. The majority are in ok condition and cleaned up nicely although I will have to replace a couple. I would much rather replace all and start fresh, but it's very hard to find the required u-bolts in Canada for a reasonable price, it would be almost $200 to replace them all! My order of u-bolts for the bunk bolsters arrived, so I will also be getting the bunk boards and carpet this week to get ready for reassembly.

Got a few more feet of paint off the bottom, the port side is now 99% complete, just have to hit the last bit with the nylon brush around the rivets. I will be continuing with the starboard side this week and I'm hopeful that paint stripping will finally be done before I have to go back to work next week. Once all the paint is off I need to begin prepping for rivets, it looks like I will have at least 5 spots to patch up on the bottom, and unfortunately 3 of them are under ribs, so those will have to come off too.

Cheers, Jared