further

Lieutenant Junior Grade

- Joined

- Jun 18, 2009

- Messages

- 1,034

Re: 1988 Maxum 1700...There's no turning back now!

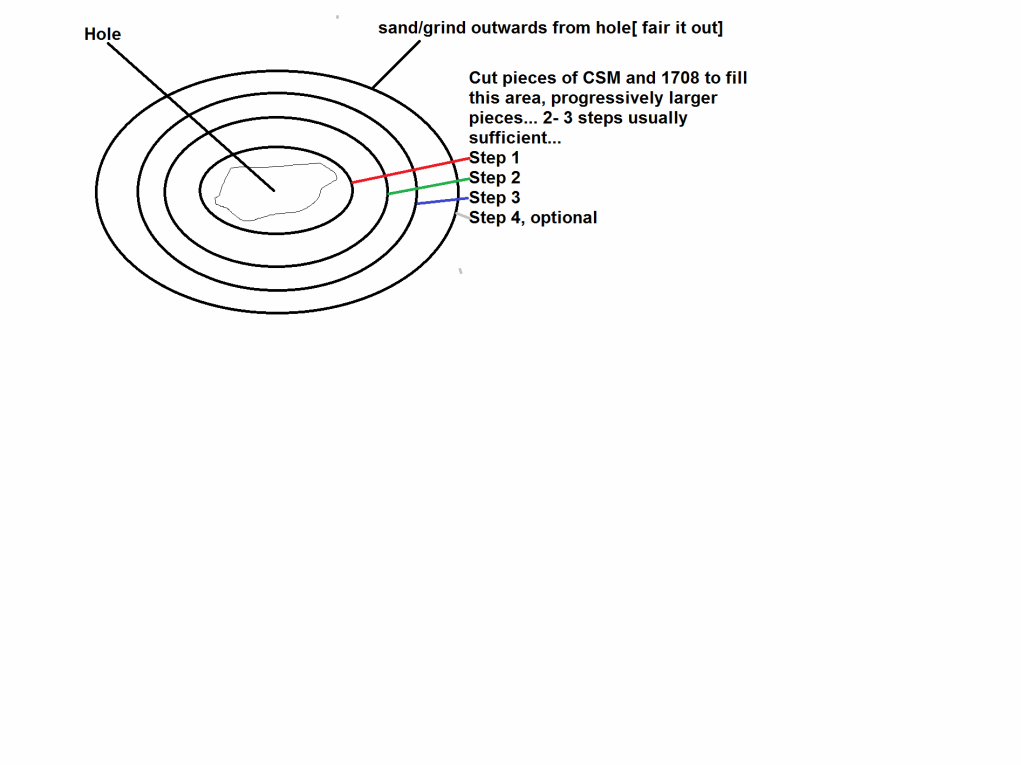

Started the grinding today and got a good amount done Ina nd around the transom. Got an issue though. Noticed a pretty good crack in the transom from the top extending to one of the through hull bolt holes.

This from the outside

This is from the inside

How would I go about fixing this??

Also, after grinding the transom, I noticed its not flat and undulates all over. I'm assuming the PB between the skin and transom will fill this in?

Started the grinding today and got a good amount done Ina nd around the transom. Got an issue though. Noticed a pretty good crack in the transom from the top extending to one of the through hull bolt holes.

This from the outside

This is from the inside

How would I go about fixing this??

Also, after grinding the transom, I noticed its not flat and undulates all over. I'm assuming the PB between the skin and transom will fill this in?