zool

Captain

- Joined

- Aug 19, 2012

- Messages

- 3,433

Re: 1988 Imperial 280sf engine swap and restoration (pics)

I see you understand where im coming from, I dont even have a box to think out of The building will be insulated and have HVAC installed.

The building will be insulated and have HVAC installed.

What it comes down to, this isnt intented to be an OSHA approved booth, and the majority of paint it will see wil be water borne latex paints..but also a significant amount of urethanes, and other finishes. Its a HOBBY BOOTH! hehe

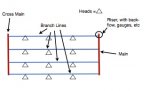

You seem to have a professional handle on this baja, and i can tell you, the calculations regarding flow and friction loss are a real PIA!.. I just settled on a tree form with the entire trunk at 1" and the branches set up under 8' at 3/4....

The biggest challenge is the PSI from a well..thats why the closed system, with a booster pump , backflow preventor, and maybe a pressure tank or ACV....

Careful with a "wet" system as it will freeze! You want either a FM200 system (pricey) or a "dry" system; however, the water source and dry valve need to be heated! There are anti-freeze systems as well, I cannot remember the name? CPVC or Blazemaster needs to be 100% sealed in soffits and chases as UV rays will break it down. Copper is a good choice; albeit, more expensive!

I once sold a stand alone "dry" system to a Big "R" farm store in Falcon, Colorado...no direct water source...when I quoted the developer over $1million for the complete code required system (100,000 gallon cistern, UL rated pump, generator with shunt, etc....), it would've stalled the store being built. I love thinking outside the box...I got the local FD (Falcon Fire, approx 2 miles down the highway, to accept pressurized dry system with smoke and heat alarms...If I remember correctly (it's been over 12 years ago) the system ended up costing them just over $35K?! When the large enough water supply made it that way it was converted to a wet system! Basically, it would alarm the FD of an alarm (whether smoke, heat or frangible bulb breakage, pressure release). Then the FD could respond with 2 engines and a Tender and connect to the FDC...that would be the sole water supply!

I like the idea, sold a ton of pre-action systems to auto body shops...my only caveat for you is be careful if the bulbs/heads get painted...they lose their respective ratings because it insulates the frangible bulbs (or fusible links). Of course, I'm not sure if you plan painting a lot?

Cheers!

~Brett

I see you understand where im coming from, I dont even have a box to think out of

What it comes down to, this isnt intented to be an OSHA approved booth, and the majority of paint it will see wil be water borne latex paints..but also a significant amount of urethanes, and other finishes. Its a HOBBY BOOTH! hehe

You seem to have a professional handle on this baja, and i can tell you, the calculations regarding flow and friction loss are a real PIA!.. I just settled on a tree form with the entire trunk at 1" and the branches set up under 8' at 3/4....

The biggest challenge is the PSI from a well..thats why the closed system, with a booster pump , backflow preventor, and maybe a pressure tank or ACV....

Last edited: