I've been measuring and sketching for the last several days and finally think I've got enough measured to at least know how much wood to buy. I'm going to buy AuracoPly plywood, as there is a supplier ~1.5 hours from me. I'm planning to buy 4 sheets of 3/4" and 4 sheets of 1/2". I should be able to fit everything on 3 sheets of each, with an extra sheet in each thickness in case I screw something up. I'm planning to replace 5 stringers, 1 bulkhead, ski locker floor, decking, engine mounts, and transom. I'm leaving the forward bulkhead and decking over the fuel tank in the bow, as there was no rot or water in that. As of right now, the plan is to start de-skinning the transom tomorrow evening.

Next up is taking a wag at how much resin and cloth I want to buy. I'm sure I'll be bouncing my thoughts off of yall regarding that in the coming days.

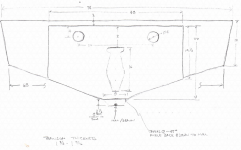

Just one of many sketches I've made over the last several days.

Next up is taking a wag at how much resin and cloth I want to buy. I'm sure I'll be bouncing my thoughts off of yall regarding that in the coming days.

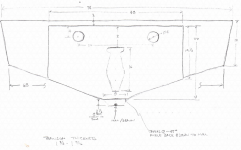

Just one of many sketches I've made over the last several days.