Thanks Guys, moving a long and really happy with the progress.

oscarvan

Its standard CDX that I covered with Blue Fasco Epoxy. Decided to give it a try and document its use for future rebuilds. Thus far it hasn't been bad for the price point. You can find some more information on the epoxy in post #258. Not a whole lot out on the web and wanted to put more out there for anyone else to find.

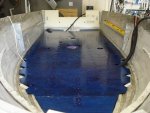

This weekend got the admiral to help out in putting down the Shark Nautolex.

Dry Fitting:

Since its 74 inches wide, decided to run it up the sides a little to provide an overlap for the top half.

Added a layer to the shelf area before doing the sides

Sides done and overlapped with the bottom. Cut out the vinyl for the access hole to the gas tank. Didn't want one of us to step on that area and go through the vinyl.....

So a couple learnings for future people putting down vinyl:

We used 6 cans of 3M 19 oz. Rubber and Vinyl 80 Spray Adhesive to complete what you see. Going to have to get some more to do a couple touch ups and future adhesion for other areas.

Make sure to have a rubber ink roller to spread out of the vinyl as you glue it down to work out bubbles

Dry fit and be willing to cut stuff into smaller more manageable sections. Admiral and I didn't initially and had issues trying to get things to lie flat. Became very difficult to work with the larger pieces/ especially the sides.

Take the time to think out what you are adhering and how you will work through it. Several times Admiral and I found ourselves having to lift up and re glue sections as we had not realized it would hinder laying down the next section.

For future, would defiantly do it again, but will make sure to cut it up into much smaller sections. Already told the admiral this was just practice until I can do a 22 fter :watermelon:

Next steps

Went to Ace to get SS bolts and screws to start putting in gunnels and seat pedestals. Realized they didn't have enough of what I needed and would need to order online anyways, so decided to just order them all. In stand still now waiting for bolts to come in. Hopefully they will be in by this weekend and I can do some more.