I've used Nautolex now on two different decks. One was over counter sunk rivets, the other over rivets that were not counter sunk. I would definitely do the counter sunk rivets if I were doing another deck.

What I would do... Seal the deck with Helmsman Spar. I feel as though epoxy would provide for better protection, but is somewhat over kill for the deck, especially under the vinyl. If you have the epoxy on hand, go ahead an use it, but I find it more cost efficient and easier to use Spar on the deck and any wood other than the transom. I have used epoxy in place of Spar for the better finish if I was planning to paint over it however.

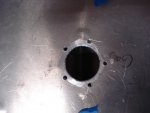

Drill, countersink, and rivet the deck in place after sealing and before the vinyl. Coat each large flange rivet with a nice dose of 3M-5200 when installing. The 3M-5200 will seal up the holes so no need to pre-drill before sealing the wood. Additionally, it's much easier to line up and hit your mark on the stringers and rib ends with one go, rather than hope everything comes together the second time around. Do one deck section at a time, then when the entire deck is installed, go back over the counter sunk rivets with 3M-5200 or Marine Tex to fill in the voids.

Lay the vinyl in one run with 3M80, contact cement, or the Nautolex adhesive.

I would recommend placing rivets in the rib ends in addition to the stringers. It really ties down the floor, tightens everything up, and from everything I can tell, this was standard practice. Granted, the side boards will aid in some security, but they do nothing for the bow or anything under the splashwell. I feel as though you'd be unnecessarily compromising the inherent structural stability of the system (deck, side panels, gunnels, consoles, etc) that were engineered to work together. It's a little extra effort in a much larger undertaking.

I'd only wrap each deck section and install independently if I anticipated ever having to remove the deck in the future.