Sorry----I see a plug where the red arrow points.----That is NOT an adjusting screw for mixture !!----Some carburetors you have to remove the float bowl to get at the low speed orifice plug.------You have to take that plug out to find the high speed orifice plug ( calibrated hole ) for fuel.-----Perhaps carburetors are not factory original.

Good news, I am NOW working from an OMC manual.

There is an orifice there, you access it as you stated. I have already made sure those are clean. The high speed orifice you can get to without taking the float chamber(bowl) off.

I believe the carb is factory original. The lasered metal tag part number(attaches with a float bowl screw) matches the part number I see in the diagrams for this motor. 393769 and 393770

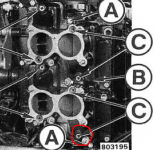

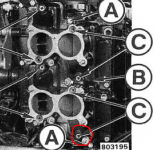

When removing the carbs , I noticed a small fuel leak at the bottom reed box screw, which the screw was not tight. Possibly this negatively impacted vaccum/suction of fuel to enter intake? Screw circled in red

The float chamber was full of gas, so I know gas is getting to the carb. I went over both carbs slowly, I was able to see light(flashlight on phone) on every hole and orifice possible. I also performed all the syringe and iso alcohol tests mentioned in the service manual, which all looked good. I can not understand why, during the suction/vaccum effect caused by the piston traveling upward, fuel is not coming up to the idle chamber via the idle emulsion tube, and out idle discharge passage to the intake.

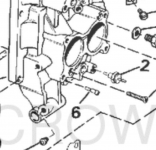

Is a bolt missing or is this not supposed to have a bolt, in the attached pics? I took one pic from further and one close up also circled in red.

Finally, the cable routing of the recirculation hoses in the manual is different than the picture of the hoses before I dissasembled. Do I trust the manual or my picture? Below is the manual. my pic has the hoses running to the check valves on the same sides.