Okay I got some more done and even the CSM has arrived. Weather is good, CSM has come in (US Composite doesn't mess around) and I managed to get the carpet pattern made.

I was waiting for the CSM fiberglass to show up and amazingly it did today. Fast shipping in my opinion. So now I can finish the live well lid the correct way.

I did get the second coat of paint on the inside of the seat boxes as well. There is only a little touch up to do with them.

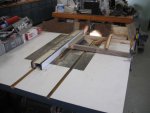

Today right before the CSM arrived, I manage to cut and make the floor carpet pattern. I took one 2 x 4 and cut it about 3/32" thick strips and laid the strips out to allow me to make a decent pattern to rough cut the floor carpet. I set us a simple jig to get each strip cut exactly the same thickness.

I know a few will think that this was totally useless, but it works and makes the rough cut a freeze. Hot glue makes the connection with the wood strips instantly and they don't move. Now I just slide the pattern out of the boat and lay it on the carpet and mark with some chalk (on the back side of the carpet with the pattern flipped over as well) and cut a little over size. Nice....

Of course cutting that many strips made a mess of table saw dust that took me about an hour to get vacuumed up. But it is now done and I will use it to cut the carpet to close size. You always allow an inch or so long on all the edges to get the perfect finish. And once you are done with the strip pattern, you have lots of stir sticks as well. :lol:

I still need to make the cushion yet. Been putting tha toff until I have to make it...and that is coming soon...

Until next update, you all have a wonderful day.