gm280

Supreme Mariner

- Joined

- Jun 26, 2011

- Messages

- 14,605

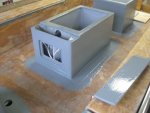

Well while I am working the rub rail insert, I am also working other boat issues as well. Yes, I did install the live well today for keeps. :whoo:

I first clamped all the hoses in place using screw type hose clamps. But I cut the extra screw strip metal material off of all of them and smoothed out the ends so if I ever have to work on any of them, I won't get cuts like you will if you don't make them smooth. Been there and done that too many time before. :cold:

Amazing how many hose clamps it took for the actual live well plumbing. I used 6 clamps just for the live well at the live well. And will use a few more at the bilge area to get the pumps and drains plumbed as well.

I mixed up what started out to be a mere 300ml of polyester resin. But I added both Cabosil and Chopped Strand Fiberglass to strengthen it to make a paste type glue, for lack of a better description. And the 300ml starting amount ended up being at lest double or triple that amount. Way more then I needed or used. Oh well, it has been a while since mixing polyester resin batches.

Then I coated the entire area between the boat floor and the bottom of the live well to make sure it stays put. I will allow that to cure and then tab it in for the final. And paint it to match the seats.

That will open the gate for the remaining carpet as well. And the only other issue with the boat will then be the wiring and mount the engine.

I see light at the end of the loonnngggg tunnel, and I don't think this time it is a train either. ray2:

ray2:

Oh and I made the decision to go ahead and cut off about two to three inches off the old rub rail insert to send to WefCo Rubber in California. Now there is no using the old stuff. Hope it works out well...:decision:

I first clamped all the hoses in place using screw type hose clamps. But I cut the extra screw strip metal material off of all of them and smoothed out the ends so if I ever have to work on any of them, I won't get cuts like you will if you don't make them smooth. Been there and done that too many time before. :cold:

Amazing how many hose clamps it took for the actual live well plumbing. I used 6 clamps just for the live well at the live well. And will use a few more at the bilge area to get the pumps and drains plumbed as well.

I mixed up what started out to be a mere 300ml of polyester resin. But I added both Cabosil and Chopped Strand Fiberglass to strengthen it to make a paste type glue, for lack of a better description. And the 300ml starting amount ended up being at lest double or triple that amount. Way more then I needed or used. Oh well, it has been a while since mixing polyester resin batches.

Then I coated the entire area between the boat floor and the bottom of the live well to make sure it stays put. I will allow that to cure and then tab it in for the final. And paint it to match the seats.

That will open the gate for the remaining carpet as well. And the only other issue with the boat will then be the wiring and mount the engine.

I see light at the end of the loonnngggg tunnel, and I don't think this time it is a train either.

Oh and I made the decision to go ahead and cut off about two to three inches off the old rub rail insert to send to WefCo Rubber in California. Now there is no using the old stuff. Hope it works out well...:decision: