BigMikey86

Petty Officer 3rd Class

- Joined

- Apr 3, 2014

- Messages

- 91

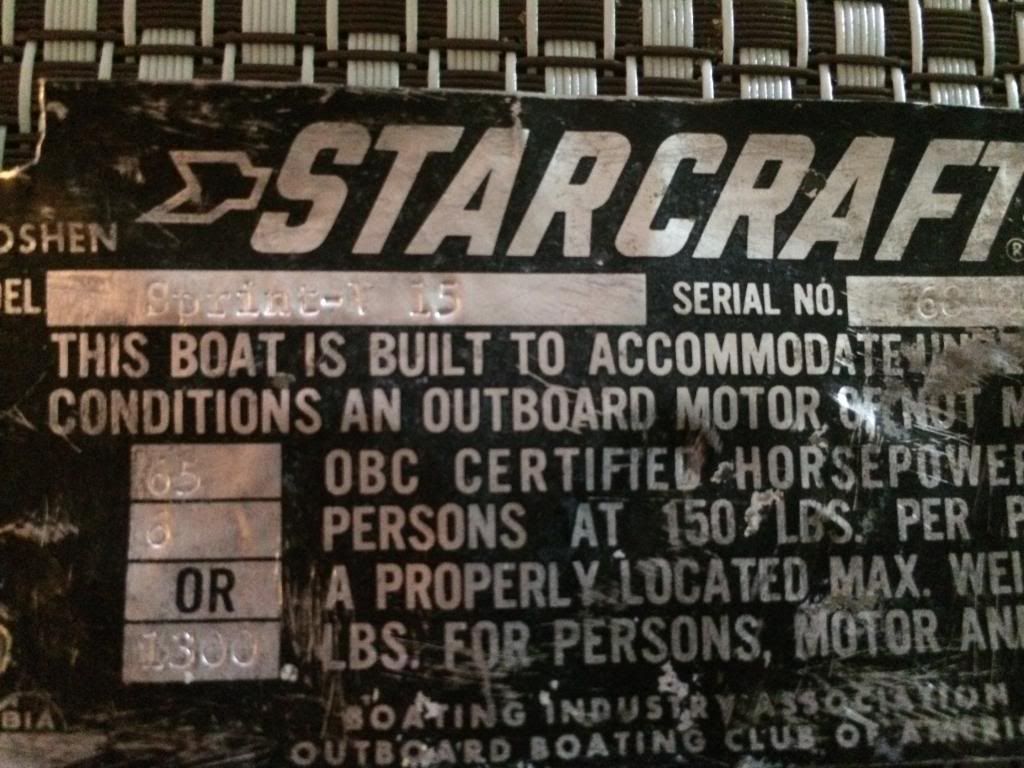

Re: 1960's Starcraft Something or other

Re: 1960's Starcraft Something or other

Thanks for letting me know watermann!. It's tough being new to the boat restoration process because everything is a learning process. I have a question though, when it comes to the rivet heads and sets. If i cant source the brazier head rivets would universal rivets or round head rivets be sufficent?

Regarding the 1/4 rivets, the PO's masterpiece he left me had those screws throw into the hull and the transom.

In a picture i haven't taken yet I've drilled out the ovaled holes to 1/4" which is why i'll be needing the 1/4" rivets. I found a air hammer with a nice sensitive trigger and a bpm of 1900. I'm hoping it will be able to set the 1/4".

Re: 1960's Starcraft Something or other

3/16" x 1/2" will cinch down perfectly through 3 pieces of .080 but may be a bit too long for 2 pieces. Not sure what your planning on banging together with those monster 1/4" but I like how you think... :heh:

Oh yeah and those 1100 grade are VERY soft and will turn to mush in a hurry on the bucktail side so do a few practice runs. I used the hard 2117 for the hull stiffeners 3/16" x 3/8" going through 2 pieces of AL and the 1/2" 1100 for the 3 pieces.

Thanks for letting me know watermann!. It's tough being new to the boat restoration process because everything is a learning process. I have a question though, when it comes to the rivet heads and sets. If i cant source the brazier head rivets would universal rivets or round head rivets be sufficent?

Regarding the 1/4 rivets, the PO's masterpiece he left me had those screws throw into the hull and the transom.

In a picture i haven't taken yet I've drilled out the ovaled holes to 1/4" which is why i'll be needing the 1/4" rivets. I found a air hammer with a nice sensitive trigger and a bpm of 1900. I'm hoping it will be able to set the 1/4".

Last edited: