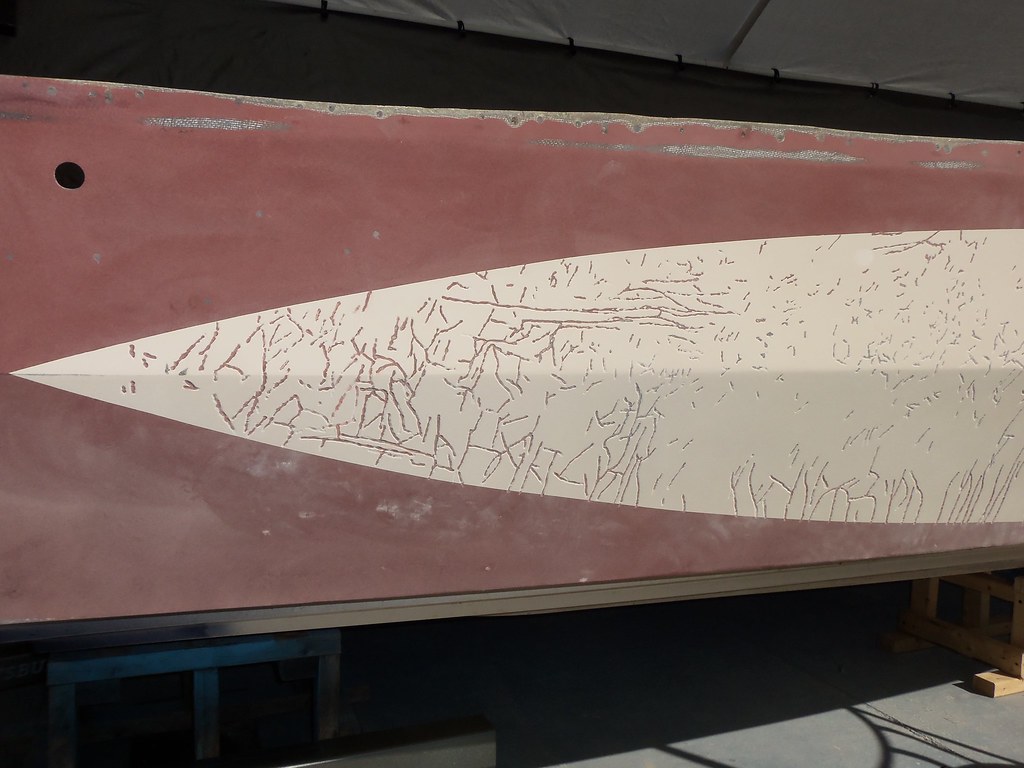

All the base coats will be piecemeal. Once everything is smooth, the final coats will be 50 gel/50 duratec. The sides will be separate sessions and bottom in 2 sections. I will use a body line to hide any blends. It has to be wet sanded and buffed anyway.

Gelcoat is very humbling. Spraying it to do touch up work is kind of black magic. There's not much info on thinning, duratec, acetone, styrene and other agents to add for spraying. The only similarity to paint is that you use the same tools to apply it. It had a very steep learning curve for me especially since most of the year is too hot to spray outdoors. I got lucky and met a marine guy that specializes in gelcoat repair. With his info and watching a bunch of YouTube videos. I think I did a pretty good job on my Correct Craft Mustang.

If you don't mind a lot of sanding you can spray two or three thinned coats. Then sanded smooth you can mix duratec with the final coat of gel and get a very smooth surface that requires a minimum of finishing. The main thing to remember is that you're not just trying to paint but creating a layer of plastic over the surface. A dump gun is great for spraying into a mold. It's also great for something you're never going to try to sand like a bilge. But unless you want to sand off 2/3 of what you spray on, learning to thin gel coat and spray in a 3 mm gun it is much more effective.

Another secret I learned is that you can keep the gelcoat in a refrigerator. The cold gel is much less likely to kick in your gun. Once it hits a hundred degree Florida boat hull it has no problems kicking off. I bought a cheap refrigerator and keep it full of all my different chemicals and painting stuff.

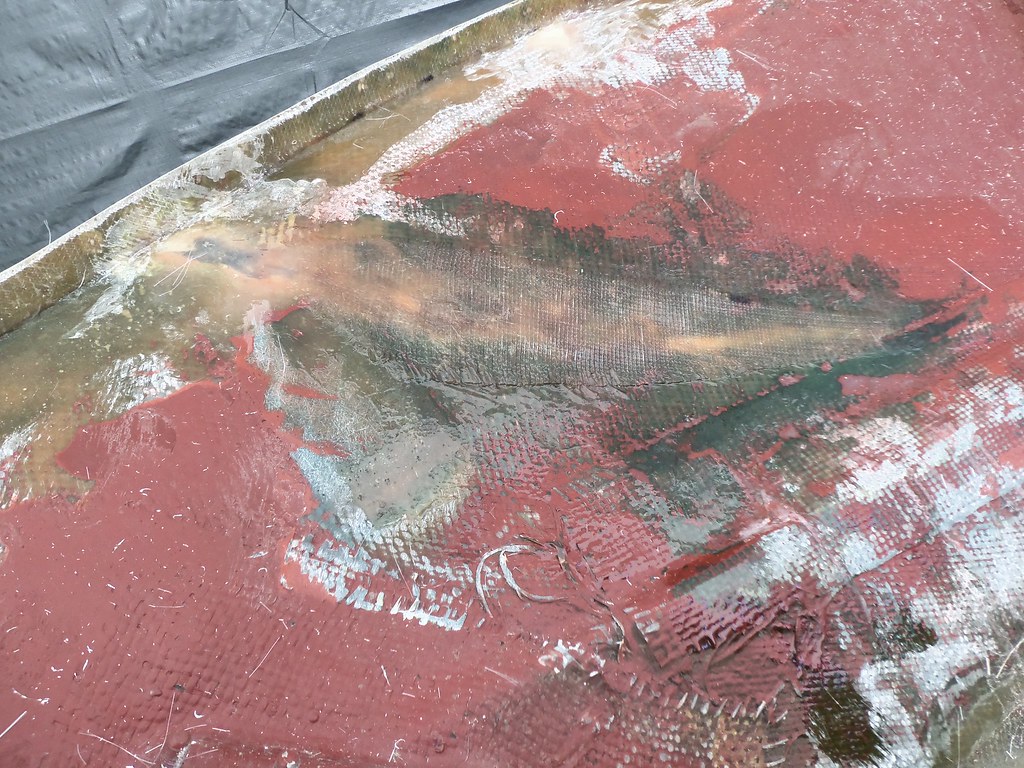

Wood: That is exactly the technique I used. I'm about halfway through sanding it all off. It shrunk a bit on me and I'm going to have to do another coat but it's working very well. Wish I had of thought of pva. I just used a little wax in the gel which it's probably going to cost me a little more work trying to add another layer. The indigo blue looks purple to me over the tan hull. Looks like I smeared grape jelly all over it.