I've mounted the hydraulic fluid tank and pump along with the control valve. I had to make a handle for the control because it was missing. Then I went and spent some cash. So far I'm into this press around $100 for parts plus consumables. I may get this brake done for around $200 plus consumables, gas and lots of time. Hey it's winter, what else can I do except to go bank fishing for poor fishing so far. However last trip I did get 1 steelhead to keep.

I found enough hydraulic hoses to connect the components so that's done.

I've ordered pulleys for the pump and motor I plan to use. I have a 2 hp single phase motor that I plan to use. It is not mounted yet because I'm waiting for it pulley. If that doesn't work I'll change it to a 3 phase either 5 hp or 10 hp that I see lying around here. In this case I prefer a single phase motor because it's simpler to bring in the wires and the circuit breaker will cost less.

I used my smallest gear pump and hope it'll provide enough pressure. While I was at it I made provisions to mount a larger pump that I have just in case. I chose the smallest one because I don't want it to move the cylinders too quickly.

The tank I have was a little cruddy inside so I threw in some 1/4" nuts with acetone and shook it up good. Lots of rusty crud came out so now it's a lot cleaner. I learned this trick from the motor cycle crowd and it worked well for the decades old gas in the Honda 90 tanks. I have a hydraulic filter between the tank and the pump just in case.

Now I'm focused on the electrical. I'm planning to use some 1" PVC that I have lying around to bring over the wiring from the 3 phase panel. I plan to pull in all 3 phases but only use the120 volt or 240 volt single phase from it initially. In fact, I may just leave the motor at 120 volts and connect it through a single pole breaker. At least I'll have options later if the 2 hp motor isn't adequate for the pump. I have some #8 AWG wire that I plan to pull but probably will put in a smaller breaker for the motor protection. That way I'll be ready in case I need to use one of the 3 phase motors.

I'm not sure what kind of hydraulic fluid I should use but I have some for a fork lift available so I think it'll give it a try.

I have a Trail Blazer meeting in Seattle tomorrow evening so I'll be away from this project a few days. It's getting close to metal bending time and back to the boat. There's another distraction awaiting but it's only a day or two to make some sinkers with claws for the Snake River springers.

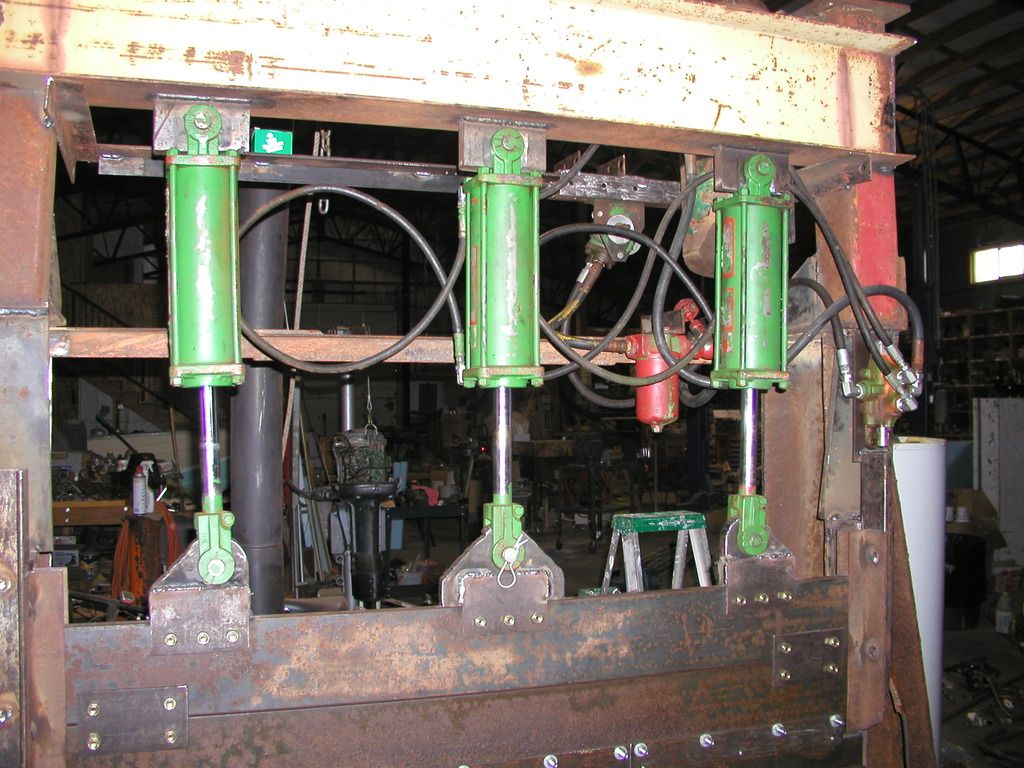

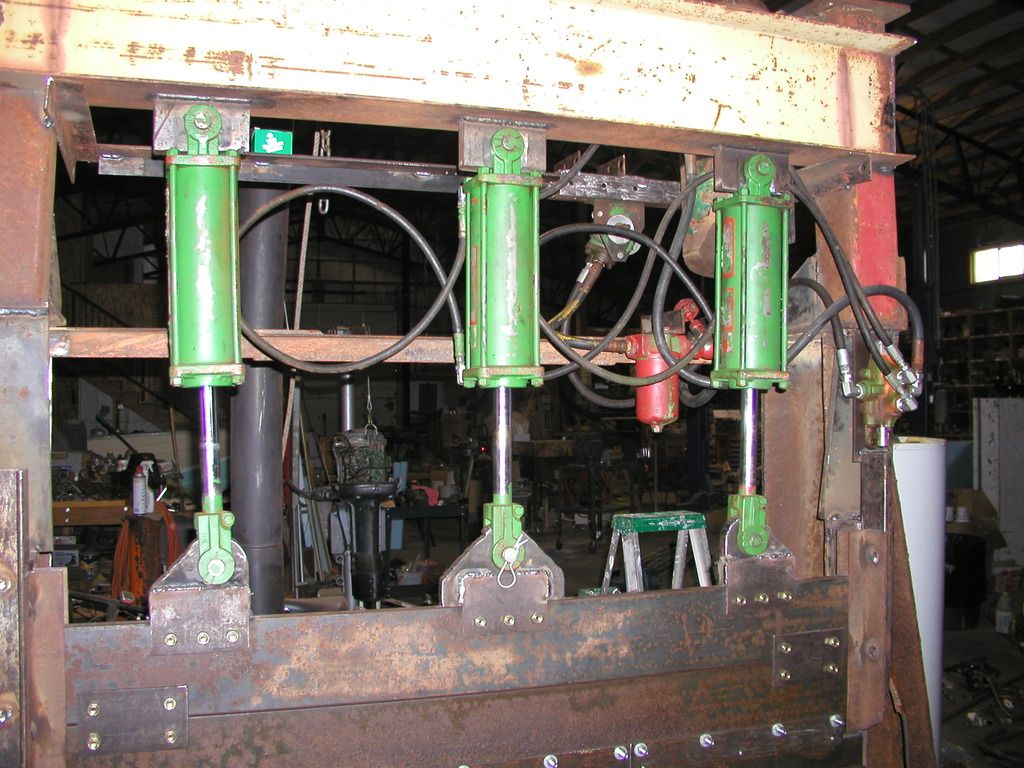

Here are some pictures.

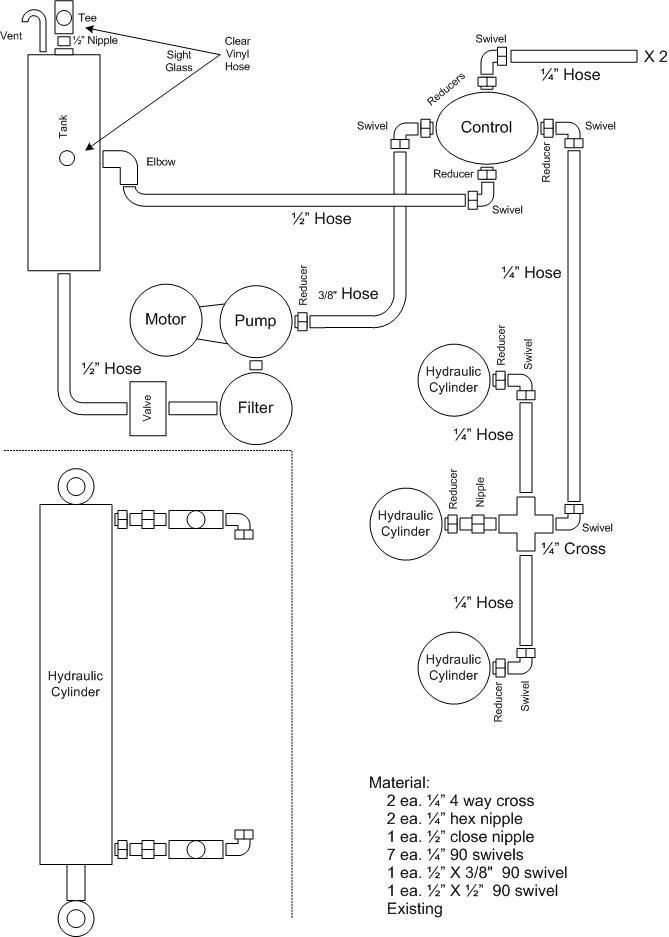

The small tubing in the top is for a vent. The open Tee will get a clear piece of tubing connected down mid way for a sight window.

The filter is red and the pump has some green on it.

A view of the pump and filter from below.

Here is the control valve without the handle.

This picture shows the 1/4" cross I used to tie the cylinders together.

This picture shows the unit with the slots milled to mount the motor. I'll have considerable adjustment for pump and motor changes.

A view from the front.

A view from the rear.

That's the latest update.