StarTed

Senior Chief Petty Officer

- Joined

- Jul 14, 2015

- Messages

- 694

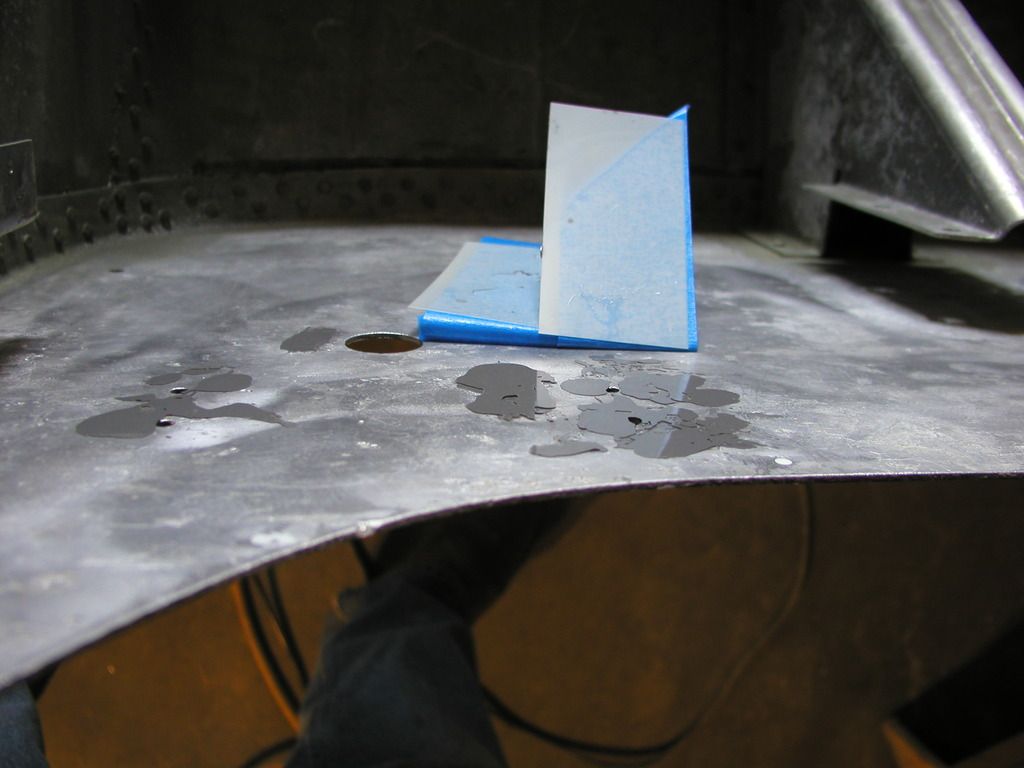

Now I'll go back to show the floor stringers. They were made from 13 gauge aluminum that is the same thickness as the transom aluminum. The shop I had make them sold me a 4X10 sheet that I purchased to add some to the transom to make it a standard shaft. They also stiffened up the bottom so there should be less flexing. We'll see.

The stringers are installed in this view and the next few.

I sure appreciate all the help I received getting the photo problem solved. The stringers were placed where I wanted them then each end drilled and fastened by Clecos to hold them while I drilled the remaining holes into the ribs. I used a hole duplicator to use existing holes as much as possible. Then I removed the stringer and deburred their holes. That made the installation with 3/16 pop rivets tighter. Each stringer is 10' long, in front of that I plan to make a raised deck.

The stringers are installed in this view and the next few.

I sure appreciate all the help I received getting the photo problem solved. The stringers were placed where I wanted them then each end drilled and fastened by Clecos to hold them while I drilled the remaining holes into the ribs. I used a hole duplicator to use existing holes as much as possible. Then I removed the stringer and deburred their holes. That made the installation with 3/16 pop rivets tighter. Each stringer is 10' long, in front of that I plan to make a raised deck.

Attachments

Last edited: