Re: 1961 Lonestar "Flamingo" - I finally Started w/pics

Re: 1961 Lonestar "Flamingo" - I finally Started w/pics

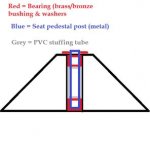

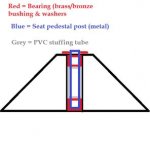

Now I had NOT thought of that but... HMMMMMMM no reason I could not do that. Wonder if it would " Wallow Out" the wood eventually?? I'm gunna have to think on that one a bit. the PVC is Schedule 80 when it's packed with Grease most of the weight will be on the stainless washers and there will we some on the shaft when a person is leaning back....

The wallow & the tension at the top lip when under load is where I was headed w/ the bronze/brass bushing Q earlier...... You could even use flanged bushings which would increase the surface area of contact to help reduce the wallow. But the bushings should probably be epoxied in...

As the seat post leans back at the top of the pyramid, under load, it is also pushing forward at the bottom, & vice versa for leaning forward, & left & right... A flanged bushing at the top could also eliminate the pyramid side post washer, just a sacrificial plastic 1 & 1 for the seat end of the post. Boring a zero clearance hole for the PVC is also going to reduce the wallow, but if you eliminate gluing (epoxy ?) it in, so the PVC is replaceable, I think it's more likely to distress & wallow over time.

Using the flange bushing at the top & a non-flange bushing at the bottom, why not select a bushing inner diameter that 'fits' the +1/32 post, and get the PVC tube to just fit OVER the outer diameter of the bushing. W/ a closed bottom on the post's hole, the assembly then acts like an inboard prop shaft stuffing tube. The now over-sized PVC creates a cavity for lithium grease (just as it does in a stuffing tube for an inboard prop shaft), and the bushings carry the load top & bottom.

This of course creates an assembly that must be completed prior to pyramid installation & is not easily repairable from above if it is glued (epoxy) in to place to reduce the whole thing from wallowing.....

The M1 Garand is often used in match target competitions, and the barrels of match guns are often bedded into a fiberglass/epoxy bed to reduce/eliminate the slop & wear on the wood stock during cycling/firing and tear down & cleanup. The same could be done prior to installing the stuffing tube into the pyramid base. Not unlike over boring transom thru hull holes, filling them w/ epoxy & redrilling the mounting holes in 100% epoxy

Hmmm...... sorry about this ^^^ esp if it isn't helping..... I hope it does.....