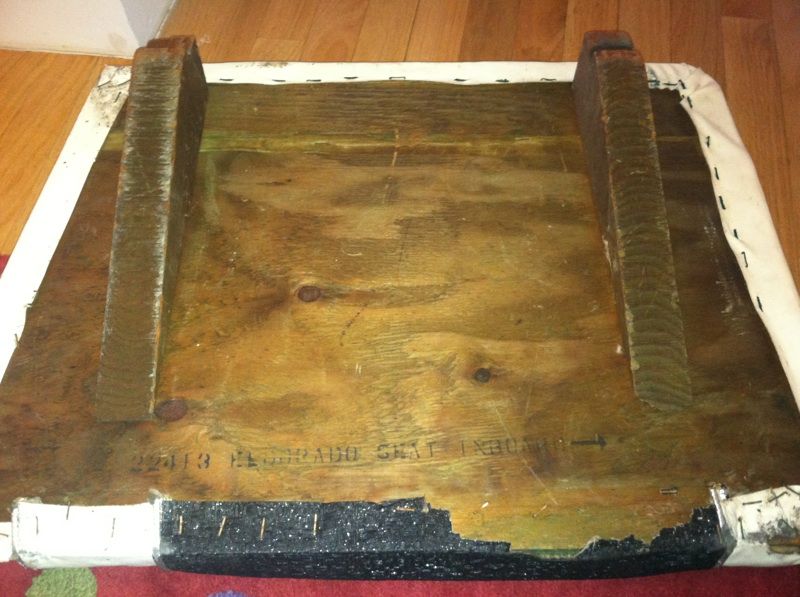

OK i am no expert but thought i would chime in on this one since my next step is to cut my floor boards for my boat. Like i said the po had one sheet of ply on the deck and two little strips on each side about 3 1/2 inches wide so where the seams where you really could not walk or put to much weight there so what do you all think about that lay out?? and i also have been thinking to cut out around the knee brace on both sides.... And luke i took my transom home and did a dry fit IT FITS LIKE A GLOVE

amazingly if it would have been a 1/4 longer in the top i dont think it would have gone in its that close of a fit.... Thanks again

What do you plan to do as a floor covering? just spar, carpet, vinyl? I don't think there are any

bad ways to lat out the floor. If I were to do it again it would be "3/4" ply wood with the seams running with the ribs. I am so glad the transom fit good! Cant wait to see yours when it gets installed.

I did some more coating with spar on my boards. The transom needs one more coat to be finished, and the others still need 2-3 more.

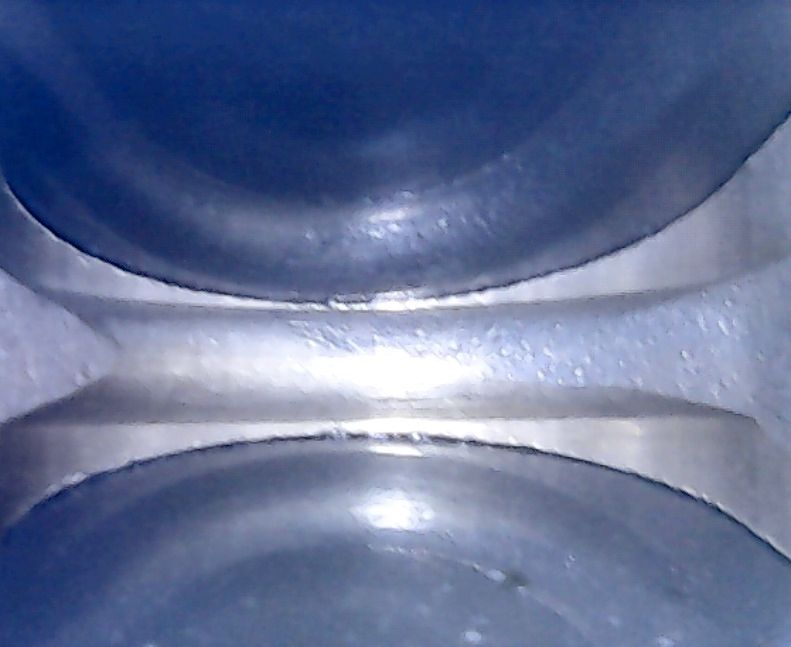

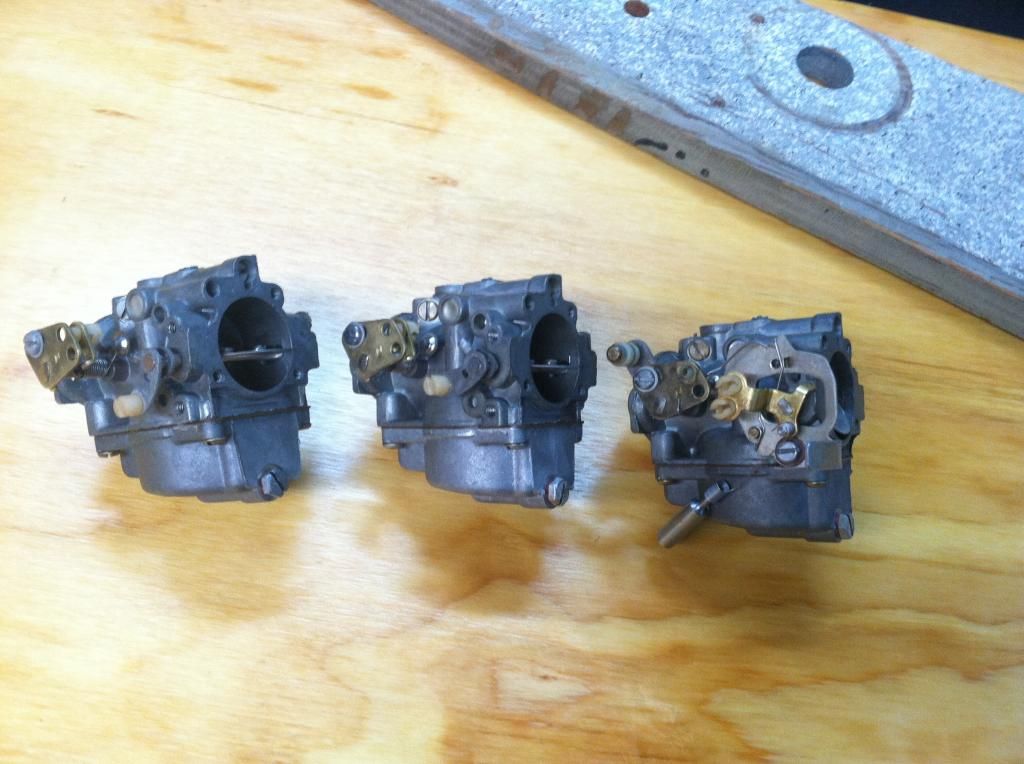

I decided to start looking on my next project, the motor. I took the hood off today to make a game plan for it. The seal was just crumbling so I took what was left off and pulled the staples. I know the gasket is no longer available so I think I am going to use automotive door trim/weatherstrip. Unless you guys know of something better? There are a lot of nicks and gouges in the hood that I want to fill in before I paint it. But there are also some larger areas of damaged fiberglass (see pics below) including one spot where it looks like the flywheel was spinning and cut through the hood. What do you guys recommend I fix this with? Also I am planning on stripping out the old foam so nothing gets sucked into the engine as the foam continues to degrade. Should I replace it with anything for soundproofing or is it just not going to do much?

Damage to corner of hood where hood meets engine:

Damage on edge:

Damage where the flywheel cut through the inside: