Luke000

Restoration Forum Splash of the Year 2016

- Joined

- Aug 19, 2013

- Messages

- 346

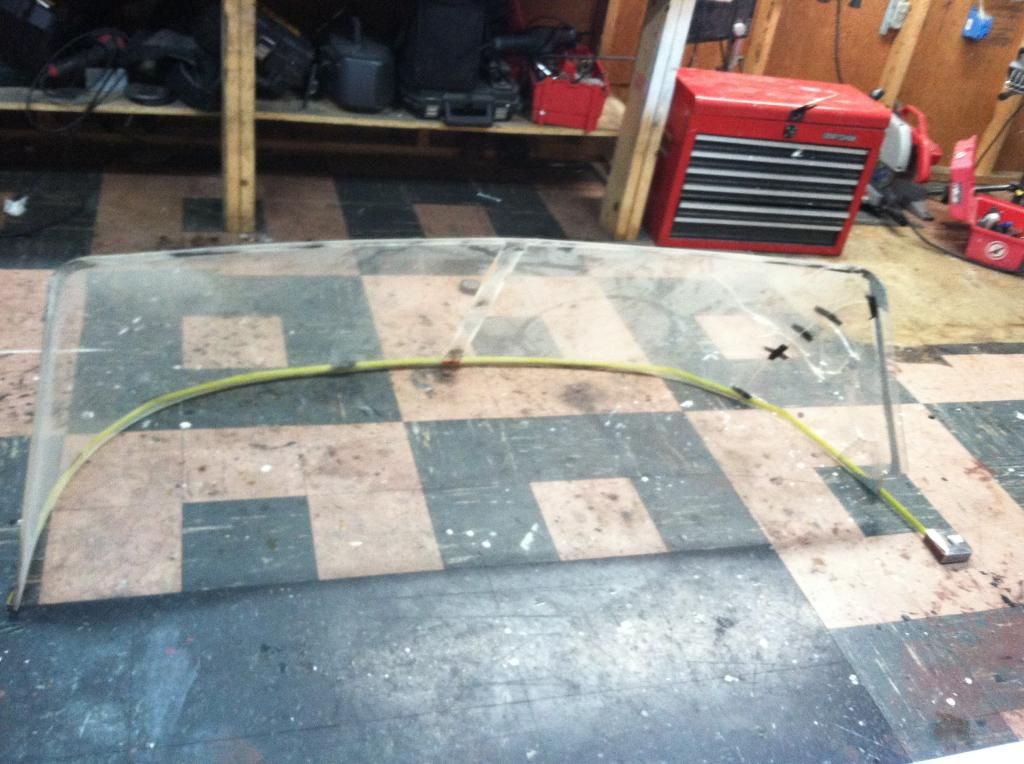

I'M BACK!! Not much work has been done, I need to wait on more funds and warmer weather for the next big steps (engine test, all paint, transom install, new windshield, etc...) But a few weeks ago I got all the boards I was working on done, sealed, finished. I got a new dash cut up out of 1" ply (2- 1/2" pieces laminated) I need to decide if i want to upholster it, or just leave it finished with spar. I started a new job last so I hope that at least the funds will start to come back :lol:. I also have a jet ski that will be going up for sale in April so that should take care of the rest. Anyways here are some pictures of the finished boards!

Transom:

Dash:

Flooring:

Transom:

Dash:

Flooring: