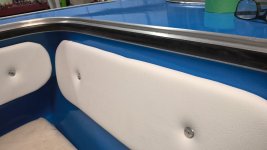

Still poking away at the boat painting process. Three coats on exterior (top three strakes), and 2 on most of the interior trim/gunnels/splashwell. One more coat on everything, and I think I'll call it done - looking forward to peeling the masking tape off, and getting on with assembly.

I had a can of the same colour aerosol Rustoleum(Tremclad), so I thought I'd use it for the awkward deep corners of the splashwell, and ended up with a disaster. Strange in that I was following the same 24 hr cure time between coats, but whatever the solvent was in the aerosol it didn't play nice with the rolled coat below. Will need to sand those spots out and try again. Hopefully it didn't mess up the primer below as well.

My last bit of painting was on a windy day, and there's some dust that made it into the finish. I think just be exiting the shop after painting, or perhaps air exchange from a leaky building caused those issues. I'll be wet-sanding and polishing once fully cured.

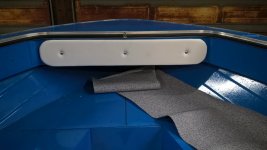

Consoles and front seat boxes are now back in for good, I hope. I'm looking at the bow area, and that section below the bow cap is really useless. The thicker-than-SS gunnels make the gap too narrow for an adult foot. It could be filled with more floatation foam and boxed shut I suppose.

Also the aluminum seat tops and front triangle were all closed in the top, requiring jamming of stuff through the side-holes. Given plywood-backed padded seats are in there providing some rigid structure already, I cut open the aluminum seat tops to give access from above that storage area. I need to find some trim to use around that cut edge. I'd like to do something similar for the bow triangle to give access to that area from above as well. Maybe a hatch is in order. The stock arrangement has another block of eps foam clipped to the underside.

I almost got myself into some serious trouble the other day, with fresh paint on exterior of hull, splashwell, gunnels, etc, leaving me no dry exit strategy! Fortunately I was able to channel my inner gymnast and arched my way over to the workbench, and down to ground level with no wet paint contact.

Still haven't decided if I'm going to stick with the flatter replacement windshield, or modify it to keep the steeper stock look. I was also considering some sort of elevated windshield setup, like the Lund below, but need to keep the 'feature-creep' in check or it'll not sail this season!