wellcraft-classic210

Master Chief Petty Officer

- Joined

- Sep 22, 2010

- Messages

- 839

Thanks!!!

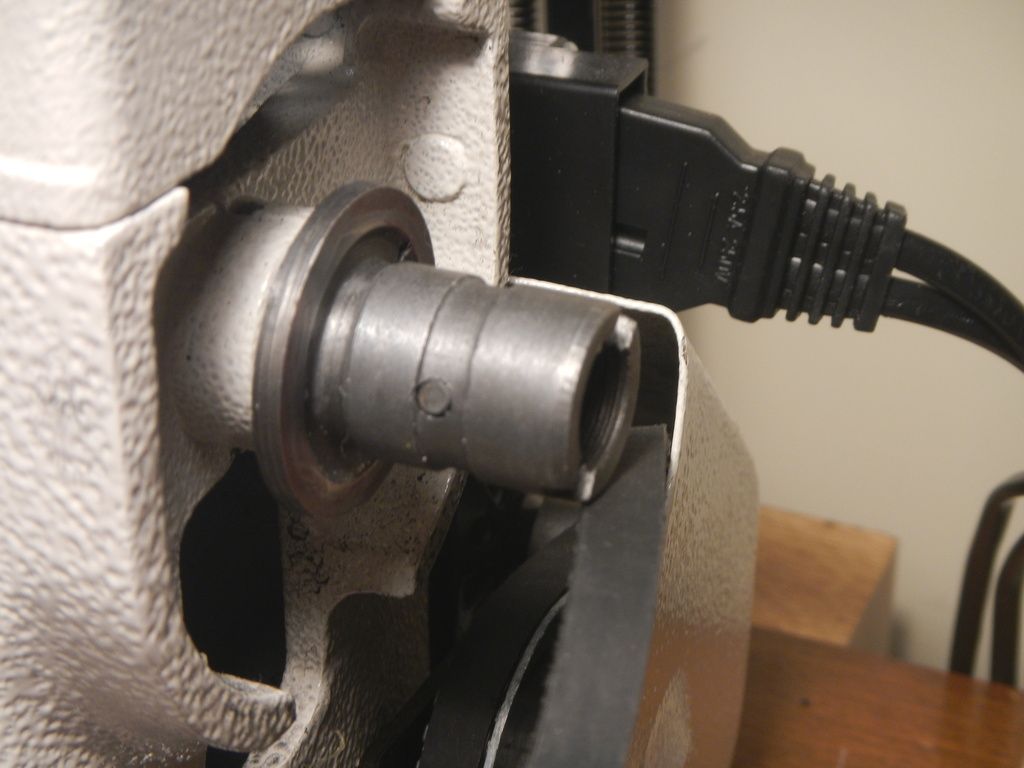

Don't even bother with a binding foot unless you get a binder.But before I take on any big cover jobs I should get a binding foot & upgrade the wheel & clutch.

Do you use Sunbrella double fold binding with that machine? Are you using a binder? Can you even get binding feet for it?Yeah, well Like I said other than the length of stitch issue my little Ole 15-91 doesn't seem to have that problem.

Do you use Sunbrella double fold binding with that machine? Are you using a binder? Can you even get binding feet for it?

The two binders that I used before were fixed and didn't swing away. Makes life hard when you want to back stitch at the beginning and end of the run. With the swing away it starts to swing when you reverse which is perfect.Yes but, never really tried it. I do all That kind of stuff on the REX 11 155R. I have the Same binding foot you have. Works Great.