Woodonglass

Supreme Mariner

- Joined

- Dec 29, 2009

- Messages

- 25,930

Re: Total Rebuild Help

Not sure I qualify as an Expert but I'll give it a shot at answering your questions...

1. The transom did warp about 1/2 inch despite my efforts to keep it from doing so. Is this ok or will it cause problems?

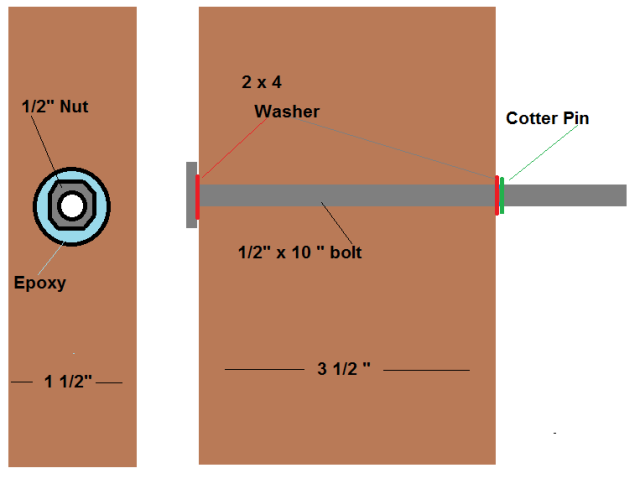

Warpage is not good but 1/2" is prolly not a show stopper. R U going to be using clamps like I have illustrated on my site?

2. I plan on removing the screws and filling the holes with PB before covering in CSM. Is this the right course of action?

Either fill em or drill em out to 1" holes and let the PB ooze thru when you clamp it home on install. This gives it more of a Mechanical bond to the hull. See the first link in my signature below.

3. It will be about 67 degrees tomorrow. How long will I need to let the first layer of CSM I apply on the transom sit before I can flip it over and do the other side? If you use 1.5% MEKP you'll have about 20 mins before it starts to set up. I wait another 20 mins and then flip it.

4. After installing the transom, how long should I wait between layups when glassing it to the hull with CSM tabs and full sheets of 1708? Same as above. Don't forget to fillet the edges and bottom with PB

Not sure I qualify as an Expert but I'll give it a shot at answering your questions...

1. The transom did warp about 1/2 inch despite my efforts to keep it from doing so. Is this ok or will it cause problems?

Warpage is not good but 1/2" is prolly not a show stopper. R U going to be using clamps like I have illustrated on my site?

2. I plan on removing the screws and filling the holes with PB before covering in CSM. Is this the right course of action?

Either fill em or drill em out to 1" holes and let the PB ooze thru when you clamp it home on install. This gives it more of a Mechanical bond to the hull. See the first link in my signature below.

3. It will be about 67 degrees tomorrow. How long will I need to let the first layer of CSM I apply on the transom sit before I can flip it over and do the other side? If you use 1.5% MEKP you'll have about 20 mins before it starts to set up. I wait another 20 mins and then flip it.

4. After installing the transom, how long should I wait between layups when glassing it to the hull with CSM tabs and full sheets of 1708? Same as above. Don't forget to fillet the edges and bottom with PB