Mick

Yes plan is to make 2 new tanks to the required dimensions as the space is limiting factor as no room in floor

missed attached photo

should be able to sale the existing fuel tanks to recoup some $, may get $300-400 for them

The existing fuel saddle tank is 560mm H x 800mm long (approx 108 litres)

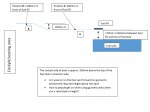

The new design I can get 400mm length back towards the transom so only 600mm sticking inside the engine bay and then reduce the height to make them fit under proposed new hatch build

the attached picture may make the concept clearer

Yes plan is to make 2 new tanks to the required dimensions as the space is limiting factor as no room in floor

missed attached photo

should be able to sale the existing fuel tanks to recoup some $, may get $300-400 for them

The existing fuel saddle tank is 560mm H x 800mm long (approx 108 litres)

The new design I can get 400mm length back towards the transom so only 600mm sticking inside the engine bay and then reduce the height to make them fit under proposed new hatch build

the attached picture may make the concept clearer