TruckDrivingFool

Lieutenant Commander

- Joined

- Jul 30, 2007

- Messages

- 1,818

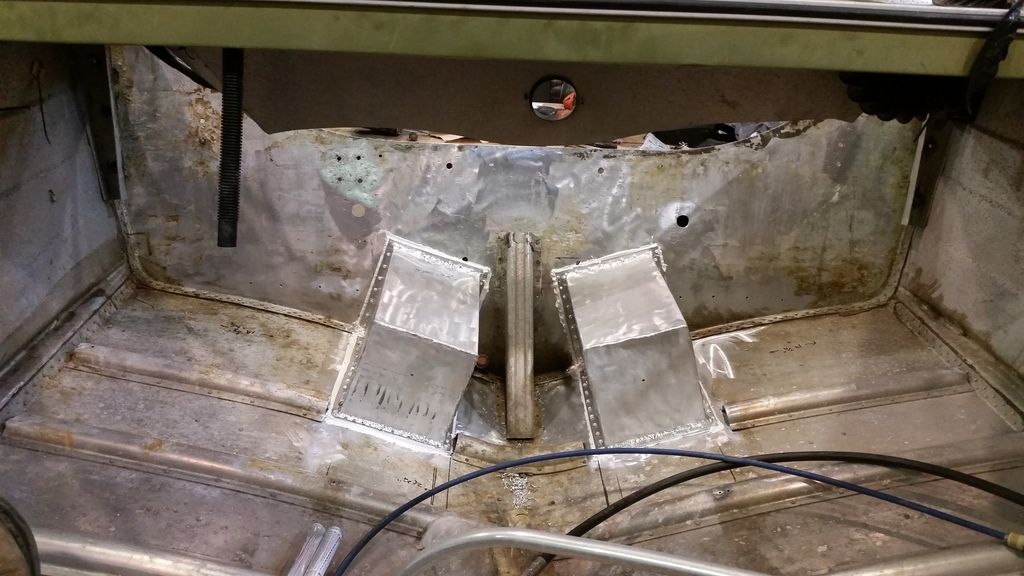

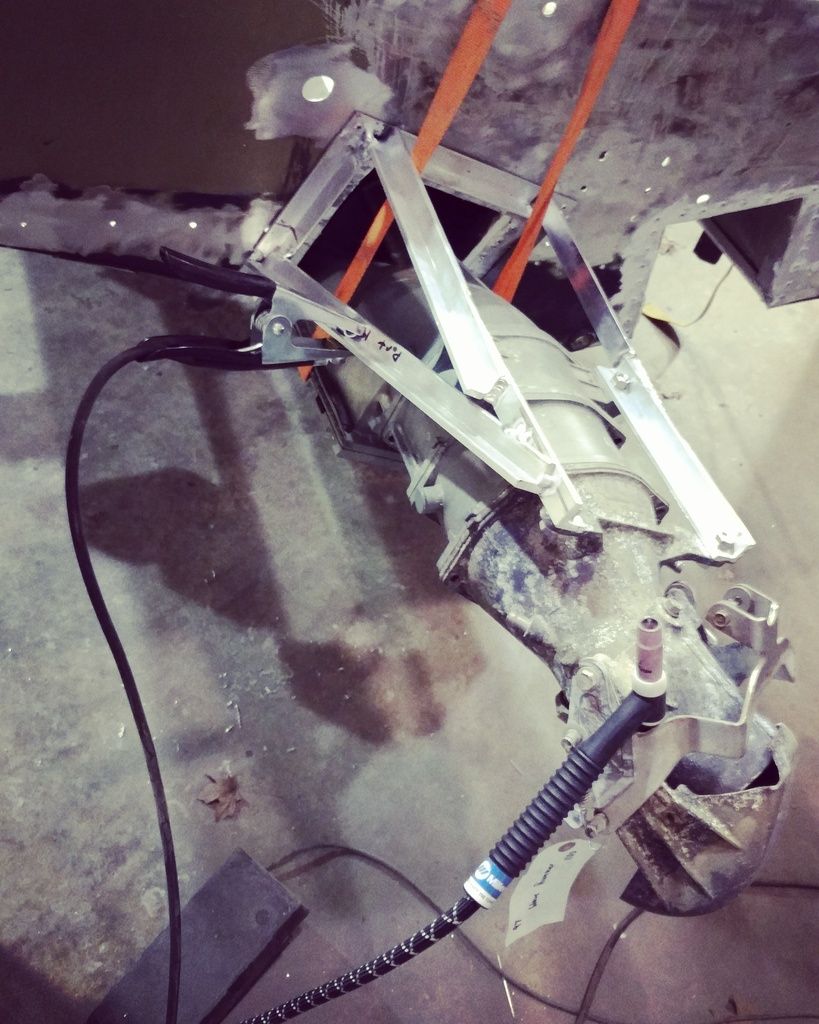

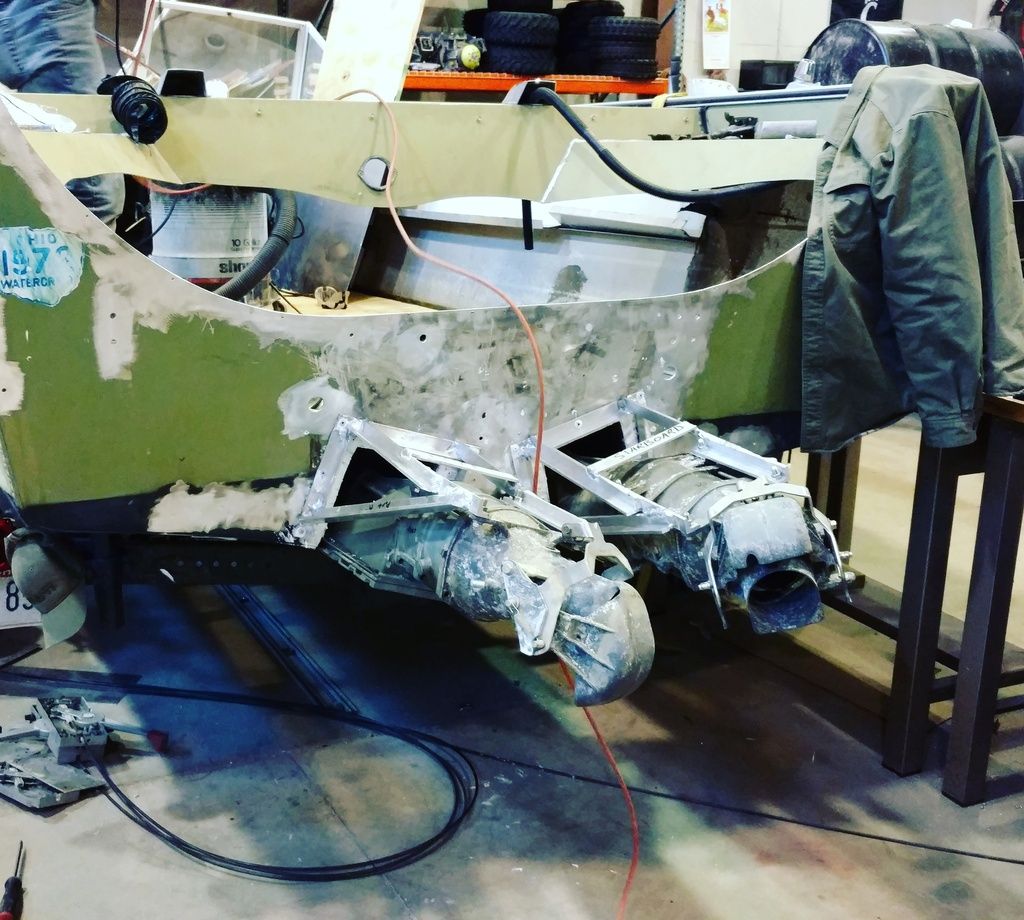

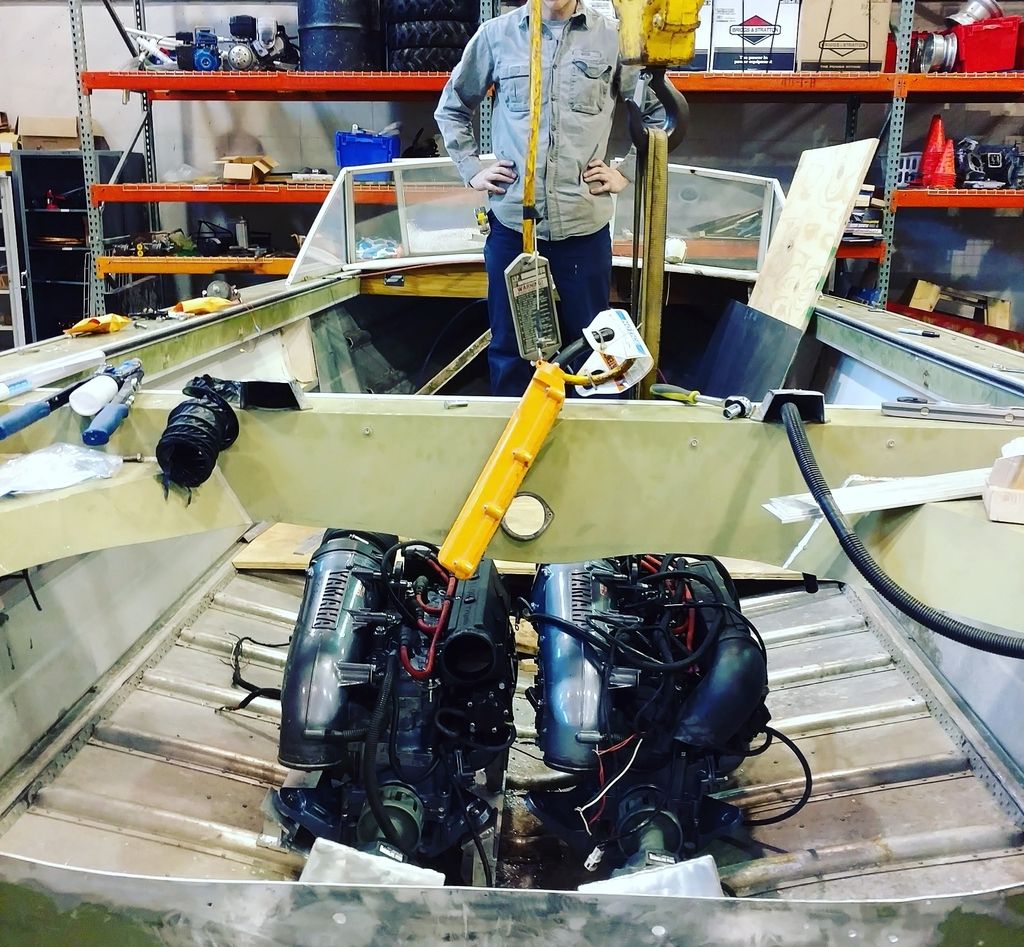

SW = Splash well.

Looking at your design plan and what you've cut looks like you're planing on leaving it in. I was thinking you'd have a more finished look and more room by removing it completely and going to a cap of sorts (like on a I/O boat) to replace the lost structural member the SW provides.

I don't have any pics from the inside with the seats out to show exactly what I'm talking about but maybe these will help

Looking at your design plan and what you've cut looks like you're planing on leaving it in. I was thinking you'd have a more finished look and more room by removing it completely and going to a cap of sorts (like on a I/O boat) to replace the lost structural member the SW provides.

I don't have any pics from the inside with the seats out to show exactly what I'm talking about but maybe these will help