jonny rotten

Petty Officer 1st Class

- Joined

- Jan 8, 2012

- Messages

- 380

Lock tight marine or 5200. Both of which are rated for deck to hull joints. Most likely lock tight. Now I'm hoping it bonds to the linseed oil. Waiting a week for the sealant on the wood to dry before installing on the boatThat wood is now full of linseed oil. I doubt that resin will adhere to that. How are you going to join the floor to the hull?

Insufficient planLock tight marine or 5200. Both of which are rated for deck to hull joints. Most likely lock tight. Now I'm hoping it bonds to the linseed oil. Waiting a week for the sealant on the wood to dry before installing on the boat

Right, I found out about it here. Sounded like the wood would last a long time with this method so I did it. Aside from my possible bonding issue with the linseed oil I still not sure what the problem is yet it's been dumped on here.You’re using the OTF method. Or Old Timers Formula homemade wood preservative. Designed to be topcoated with spar varnish etc. You might want to start over with fresh ply and save the OTF ply for another project

or if you’re mechanically fastening it, simply finish with Spar and cover it with nautolex.

That’s what I did with my transom and will be doing with my floors. But I’m mechanically fastening in an aluminum boat. Are your floors supposed to be glassed in? Or are they non structural? I don’t know glass boatsRight, I found out about it here. Sounded like the wood would last a long time with this method so I did it. Aside from my possible bonding issue with the linseed oil I still not sure what the problem is yet it's been dumped on here.

The plan was Seal it, install it, roll out spar after installed and carpet I read in another forum it will and did bond permanently to other peoples boat with dried linseed so I'm hoping for the best

Fiberglass boat decks need to be fiberglassed in they are a structural member of the hull. The method being used is for and should only be used on aluminum boats.That’s what I did with my transom and will be doing with my floors. But I’m mechanically fastening in an aluminum boat. Are your floors supposed to be glassed in? Or are they non structural? I don’t know glass boats

Yes you can. Poly resin is what most people use. Most do the PB to fill any gaps and make a curved join and then put glass over that.Can you use polyester resin with either a glass strip to bond deck to hull. Or make peanut butter out of polyester resin for a deck/hull bond instead of epoxy?

Great. Does it need to be 1708 cloth or will any cloth work? Doesn't matter what it looks like it's getting carpet over it Will one layer of cloth be enough or do I need more layers?Yes you can. Poly resin is what most people use. Most do the PB to fill any gaps and make a curved join and then put glass over that.

I'm going to fiberglass it to the hull and fiberglass all seams in plywoodFiberglass boat decks need to be fiberglassed in they are a structural member of the hull. The method being used is for and should only be used on aluminum boats.

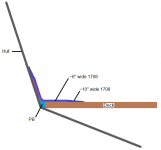

Thanks for the detailed information. When you say 2 layers does that mean one layer, wait to dry and do the process again or double up on the fiberglass and do it all at once?Use PB as a "glue" to attach the deck to the stringers and the edges to the hull. Also use PB to make fillets for smooth transitions between the deck and the hull. Ideally while the PB is still wet, lay 2 layers of fiberglass tabbing across the deck/hull joint - the first layer cut to strips ~6" wide, the 2nd layer cu the strips to ~10" wide. I recommend 1708, but you could probably use woven roving or something else structural if you want. I would not use CSM for structural repairs (and this is a structural repair).

For joints/seams in the deck, I also put some PB in the joint. I laid glass over my entire deck when done, but if you aren't going to do that, you may want to at least lay a strip of glass over the joint, as you stated.

Lay the PB in and make a fillet. While the PB is still wet, wet out and lay down the ~6" wide strip of 1708 with ~3" on the deck and ~3" on the hull. While that's still wet, wet out and lay down the ~10" wide strip of 1708.Thanks for the detailed information. When you say 2 layers does that mean one layer, wait to dry and do the process again or double up on the fiberglass and do it all at once?

OK so the PB and the fiberglass all get's done at the same time wet. I thought PB one day and the rest another day.Lay the PB in and make a fillet. While the PB is still wet, wet out and lay down the ~6" wide strip of 1708 with ~3" on the deck and ~3" on the hull. While that's still wet, wet out and lay down the ~10" wide strip of 1708.

View attachment 340675

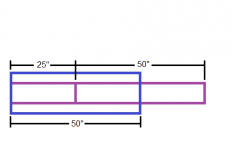

You have to work in sections to keep everything wet. If you try to lay all your PB down at once, then come back and lay all your 6" wide strips down, etc., you likely won't have enough time before the resin starts to kick. I did strips as wide as my roll (50"). Ideally you should make it where the seams between the 6" strips and 10" strips don't line up. I started by piping PB for 75", then laying a 25" x 6" strip and a 50" x 6" strip to cover the PB, then a 10" x 50" strip over that. After that, you just build onto the end using 50" strips - lay PB, lay one strip of 6", then one strip of 10", then repeat.

View attachment 340676

Great. I've never done any fiberglass work. Learning as I go. I'll do it your wayI mean you can let the PB set, and you can let the first layer of glass set, but you may need to go back over it with some sand paper to knock down any hairs or high spots. I like laying things wet on wet when possible because it drastically reduces air bubbles from uneven sub-surface, since the sub-surface is still liquid it lays down much nicer. By no means do you need to use this method though. If the PB starts to kick, you'll know it. If you are still putting it down, it won't meld with the rest of it as well. If it's already down, it won't feel as soft and moldable...more like a jelly that rapidly turns into a rock, haha.