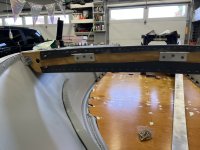

Been a busy week! Nautolex down, hull supports solid riveted in, gunnels attached, hull painted...making progress.

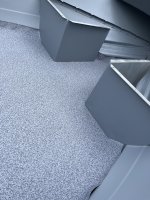

First pic of the vinyl was before I glued it down, so may look a little wrinkled. Also could have done a better job sanding some of my hole fills on the gunnels, but they'll still get a coat or two rolled on with the Epifanes beads, and some will be covered with rod holders, Cisco tracks, and other strategically placed cleats and the like, so shouldn't be too noticeable when all is said and done. Hull is battleship grey, with select interior sides, center console, and seat finished in a light grey. You can see the contrast between the two greys in some of the pictures. I was able to borrow a neighbor's 5.5hp gas compressor he used to use for roofing to shoot my hull and it was a night and day difference from my 1.5hp electric I struggled through all the interior parts with. I didn't thin any of the primer/paint and took a 5/64 drill bit to drill out my 1.4 and 1.5 tips on my HF hvlp guns to ~2.0. Worked like a champ!

I have the bow supports cut from 3/4 ACX ply, along with the side support/rod holder mounts, with the bow supports coated in spar and what was left of my epoxy on the side supports/rod holders. Still need to secure the bow supports and rivet on the bow cap, and the side supports will get a few coats of paint. Was going to use hdpe for the side supports, but figured I'll see how the epoxy coated ACX holds up and save myself a few pennies.