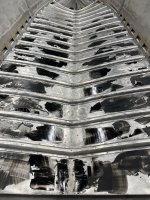

Had some nice(er) weather last week with temps above freezing, so I pulled the hull out onto the driveway, gave her a nice vinegar bath, and rinsed her with the pressure washer. Now hovering around 0 degrees here in MN, so she's back in the garage with the heat up to 65 waiitng for the 1st round of Marine-Tex to cure. Buttered over the pitting on the inside splashwell skin, filled any holes I won't be re-using, and filled in the pitting inside the hull from the saturated factory pour-in foam. The PO had done a previous redeck from a "qualified" marine shop, but it appears they used pressure treated ply for their materials. Where the front bow piece edge met the hull, there was significant surface pitting on both sides, and a small pinhole through the hull that will get a new solid rivet punched through. Also pretty significant corrosion on the tops of the floor braces/stringers where the decking was attached, more like from the self-tapping hardware that was used. That will all be getting addressed with the Marine-tex as well. Only found one other pin hole that made it all the way through the hull. The rest of the pitting appears to be pretty minimal surface pitting that is all getting skimmed with Marine-tex before I hit the seams and rivets with Coat-it.

Also managed to transfer the primary 115hp Tower of Power from one somewhat questionable stand to the more robust stand that I had built for the original motor. Much more comfortable with it now and gained a little space back with the removal of the extra stand.

Pics were before Marine-tex, but hadn't posted in awhile and wanted to get something out there for the mob. Waiting on a second batch of Marine-tex to show up so I can finish the job and move on to the Coat-it.

Couple of questions:

1) Will Marine-tex on the stringers hold the rivets for attaching the decking, or should I add another piece of aluminum?

2) I've seen some inside hulls painted with Coal tar epoxy. Any benefit on using something like this to completely seal over the Marine-tex and Coat-it, or is it a wasted effort/expense? I do not plan to ever re-do this hull down the road, just want to do my due diligence in sealing everything up. I never had the corrosion/pitting issues to deal with on my previous builds.

Happy New Year everyone!!