classiccat

"Captain" + Starmada Splash Of The Year 2020

- Joined

- Dec 20, 2010

- Messages

- 3,412

Re: My First StarCraft; 1975 18' SuperSport

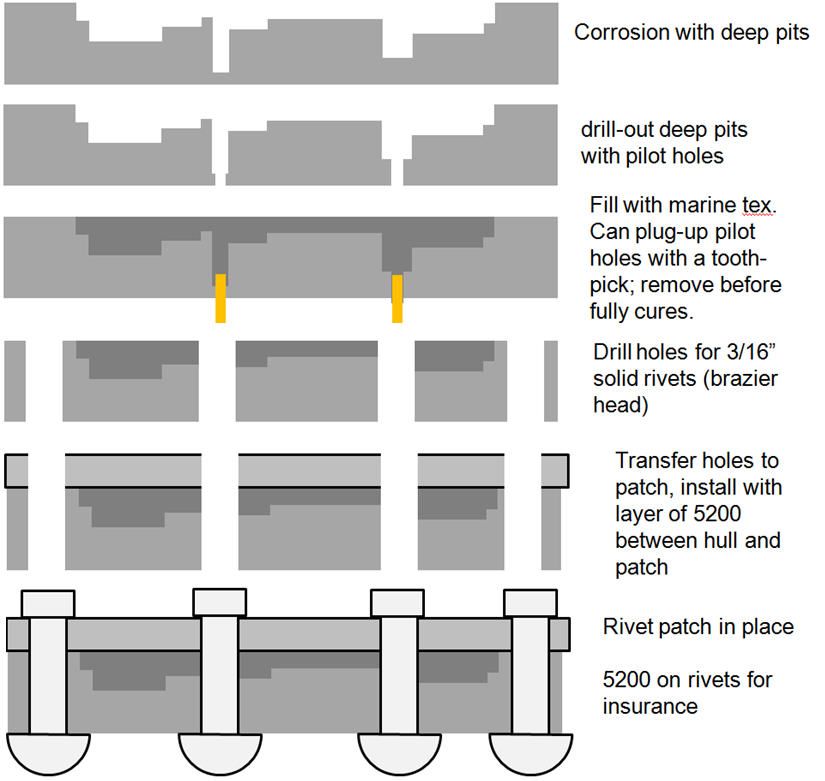

Thanks for the tips P! Marine tex is in my future here...I have a feeling that I'll need a few more boxes :facepalm:

Cool! My buddy goes-up once-or-twice per summer for smallies and pike. His uncle has a summer home on Hog island (how cool of a name is that!?!)

Thanks for the Media-Blasting cliff notes Yeonik! If/when I'm done restoring the SS, the exterior of my BlueFin looks like butt...soda blasting might be the ticket.

Yeah, this boat had 1 foot in the grave and the other on a banana peel. Good on you for saving her...

I think MarineTex and/or JB weld can curb and shore-up those corrosion areas...

I have been really happy with the way MarineTex has performed on some spot repairs I did prior to primer and paint...

That hull clean-up looks amazing BTW.

Thanks for the tips P! Marine tex is in my future here...I have a feeling that I'll need a few more boxes :facepalm:

Please do...at the very least I can point you toward the good ramps, but I'd love to do some fishing with a fellow tinhead! The Champlain fishery is getting better every year. Very good management from the VT and NY wildlife and fisheries folks. Worth the trip, IMHO.

Cool! My buddy goes-up once-or-twice per summer for smallies and pike. His uncle has a summer home on Hog island (how cool of a name is that!?!)

Bluefin, the idea behind sodablasting is that the soda is sharp, so it cuts into anything in it's way that's soft - i.e. paint, corrosion, etc. but it's also soft so it breaks on anything hard - metals, glass, etc. It's not supposed to damage the aluminum. With it corrodded like that... iono, I'm not a soda blaster ;p

At work, I run corn cob in my sandblaster - it isn't as efficient, but sand will peen steel, where the cob won't. Haven't tried it on an 'ol tinnie (yet).

Thanks for the Media-Blasting cliff notes Yeonik! If/when I'm done restoring the SS, the exterior of my BlueFin looks like butt...soda blasting might be the ticket.

Thanks Jim and Wow! I didn't know you had to chuck a hull!! Maybe on deep-pitted areas I add aluminum patches on the outside. The 2 holes that already corroded through need patches on both inside-and-out. The one one hole is right-up against the bow plate:Ok... I prolly should chime in here as Jupiter I ended up at the scrap heap! BF --- I would suggest that you pick at those areas with a sharp pointed object or screw driver... make sure they are not about to be through holes. Corrosion kinda swiss cheeses the alum... I wouldn't want to see you go all the way though the rebuild only to find the hull cracks at the corroded spots. Just worth the extra check man!

Great progress though... keep it rollin'!!!!

Jim