ratdude747

Chief Petty Officer

- Joined

- Sep 30, 2023

- Messages

- 420

After buying another trailer and finding out it's maybe not what I want or worth the effort, I am looking to see the feasbility of modifying the trailer I already have to better serve my needs. It's a 1975 Art Roll Manufacturing "Trail-R-Craft".

History: This is the second trailer the boat (A 1976 Starcraft Montego) has ridden on. The original was a low and wide aluminum twin-axle, but the original owner's situation at the time dictated the use of a narrower trailer; this trailer was traded for it. While it has worked all these years, there's a few places that I think could be enhanced.

Issues/Modifications:

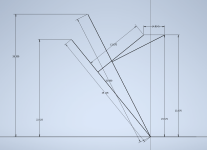

First, The trailer seems to be a bit too big. The winch stand is all the way back, but there is nearly 1' of bunk overhanging:

Note that the only thing contacting the back keel roller is the outdrive. Also note that the winch stand is very rusty... and is also ballooned, likely from water freezing after a noted "left in the rain for 6 weeks at a marina" incident 14 years ago. I wonder with a new winch stand/mount the roller contact point could be moved back to get the bunk ends and keel roller closer to the transom of the boat?

Reasons for wanting the change this is partially to make trailering/launching a bit easier (no need to dip the trailer as far), but also as a structural improvement (less stress on bunks) and to allow for full travel of the outdrive without bashing the keel roller.

Thankfully, the fender/axle assembly can be moved on the frame to allow for re-balancing of the tongue weight:

(It is attached to the main frame with U bolts)

The frontmost keel roller is also movable on the center beam... so that could be slid back the appropriate amount when the time comes.

Second, I'd like to add electric trailer brakes. Originally I was thinking I'd need a new axle (part of why I bought another trailer), but as I rediscovered today (and what prompted the change of heart), apparently I already have the flanges for such:

Thus, it should be more or less "trivial" to add electric trailer brakes. One question is how to route the wiring... currently the wiring is run through the frame rails via holes torched in the bottoms of the side tubes:

(taillight wiring)

I can't add another hole in the bottom of the side tube due to how the sliding fender/axle assembly mounts... would I need to run through the same exit hole and then zip tie the wiring back up the outside of the tube to the axle? Or would I want to drill an exit hole in the side of the tube (towards the bottom)? I'm leaning towards the former, as tacky as it may be for structural reasons.

I'd likely also add a breakaway safety (not required in IN due to being under 3500lb, but still)... My truck already has a proportional brake controller (Primus IQ) for use with another trailer I own. My truck's brakes kinda stink (1980's for ya)... and last year the brakes were an issue.

Third and finally, I'd like to add bow steps and (eventually) a spare tire mount. Both of these are obtainable bolt-on items, but I figured I'd mention it.

Thoughts/advice?

History: This is the second trailer the boat (A 1976 Starcraft Montego) has ridden on. The original was a low and wide aluminum twin-axle, but the original owner's situation at the time dictated the use of a narrower trailer; this trailer was traded for it. While it has worked all these years, there's a few places that I think could be enhanced.

Issues/Modifications:

First, The trailer seems to be a bit too big. The winch stand is all the way back, but there is nearly 1' of bunk overhanging:

Note that the only thing contacting the back keel roller is the outdrive. Also note that the winch stand is very rusty... and is also ballooned, likely from water freezing after a noted "left in the rain for 6 weeks at a marina" incident 14 years ago. I wonder with a new winch stand/mount the roller contact point could be moved back to get the bunk ends and keel roller closer to the transom of the boat?

Reasons for wanting the change this is partially to make trailering/launching a bit easier (no need to dip the trailer as far), but also as a structural improvement (less stress on bunks) and to allow for full travel of the outdrive without bashing the keel roller.

Thankfully, the fender/axle assembly can be moved on the frame to allow for re-balancing of the tongue weight:

(It is attached to the main frame with U bolts)

The frontmost keel roller is also movable on the center beam... so that could be slid back the appropriate amount when the time comes.

Second, I'd like to add electric trailer brakes. Originally I was thinking I'd need a new axle (part of why I bought another trailer), but as I rediscovered today (and what prompted the change of heart), apparently I already have the flanges for such:

Thus, it should be more or less "trivial" to add electric trailer brakes. One question is how to route the wiring... currently the wiring is run through the frame rails via holes torched in the bottoms of the side tubes:

(taillight wiring)

I can't add another hole in the bottom of the side tube due to how the sliding fender/axle assembly mounts... would I need to run through the same exit hole and then zip tie the wiring back up the outside of the tube to the axle? Or would I want to drill an exit hole in the side of the tube (towards the bottom)? I'm leaning towards the former, as tacky as it may be for structural reasons.

I'd likely also add a breakaway safety (not required in IN due to being under 3500lb, but still)... My truck already has a proportional brake controller (Primus IQ) for use with another trailer I own. My truck's brakes kinda stink (1980's for ya)... and last year the brakes were an issue.

Third and finally, I'd like to add bow steps and (eventually) a spare tire mount. Both of these are obtainable bolt-on items, but I figured I'd mention it.

Thoughts/advice?