Jeep,

Ya might, if you haven't already, have to make sure the handle/throttle assembly is back together all the way to get it to fire up.

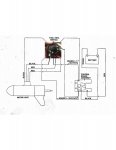

I picked up a board like yours just out of curiosity and as such..........

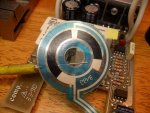

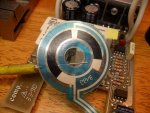

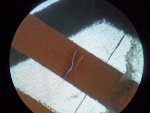

I haven't drawn/scoped it out too much yet, just got it but, it looks like the handle/throttle assembly must have a button of sorts on the back side some wheres that,...........when the handle/throttle is assembled and in proper place, the button on the back side of the throttle presses in on and rotates about the face (layer 1, see picture A) of this two layer flex cable embedded potentiometer (pot) area.

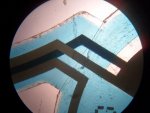

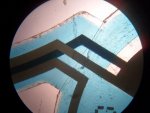

As the throttle is rotated, the button is at the same time sliding on the flex cable layer 1 and pressing it into the pot's carbon area layer 2 (see black/dark areas [Fwd and Rev] picture B) creating a varying resistance. This then develops a varying voltage sensed by the on-board circuity (comparator) and appears to be used to turn on the relay's. It is also is used to vary the PWM of course..

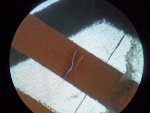

Mine has a crack (might check yours too! could be a issue for you as well) in a flex trace i'll have to fix but, once I repair it, I'll fire it up and grab some wave forms/reading and post then along with a drawing of the board.......BTW, we can bypass that main switch and eliminate it as a possible issue if need be......Lets first get the board powered up, my gut says the switch is fine.

Pic A

Pic B