lundnisswa

Petty Officer 1st Class

- Joined

- Mar 2, 2008

- Messages

- 245

Re: Lund Nisswa Restoration

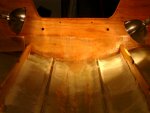

Keel Patch

Back to the previously mentioned Keel Rub through, I ground it down until I did not dare grind any more, I actually was through the hull and down to that keel guard which I left attached for now so I would have a backing for the Patch.

Once again, I did my best at this by making three patches of 1708, each 2inches larger than the next, acetoned the area thoroughly-let it dry and applied the patches, man is that 1708 thick compared to the 6 oz I had been using, and it drinks Resin, it was actually hard to get transparent, then when all done some bubbles started to form, so I used those bubble rollers and it pushed them out pretty well.

If not good enough of a patch job on the inside I can always grind it back off, I am also going to put a patch on the exterior.

Had some left over Resin, so I mixed up a small batch of milled fibers in a small cup, very thick, hard to do but I sucked it up into a turkey injector, I had previously prepped some small Transom bolt holes from old transducer mount bolts, with tape on the outside- I injected the holes from inside the boat, turned out great.

OK, let me know if I goofed up that patch, I will grind her back off.

Lund

Keel Patch

Back to the previously mentioned Keel Rub through, I ground it down until I did not dare grind any more, I actually was through the hull and down to that keel guard which I left attached for now so I would have a backing for the Patch.

Once again, I did my best at this by making three patches of 1708, each 2inches larger than the next, acetoned the area thoroughly-let it dry and applied the patches, man is that 1708 thick compared to the 6 oz I had been using, and it drinks Resin, it was actually hard to get transparent, then when all done some bubbles started to form, so I used those bubble rollers and it pushed them out pretty well.

If not good enough of a patch job on the inside I can always grind it back off, I am also going to put a patch on the exterior.

Had some left over Resin, so I mixed up a small batch of milled fibers in a small cup, very thick, hard to do but I sucked it up into a turkey injector, I had previously prepped some small Transom bolt holes from old transducer mount bolts, with tape on the outside- I injected the holes from inside the boat, turned out great.

OK, let me know if I goofed up that patch, I will grind her back off.

Lund

Attachments

Last edited: