GA_Boater

Honorary Moderator Emeritus

- Joined

- May 24, 2011

- Messages

- 49,038

Yes, inside the hull.

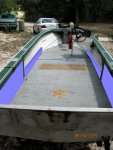

But I know that I'll need to tilt and maneuver the hull into odd positions in order to get the Gluvit to flow to the correct spaces. Doing that off the trailer should be easier, plus I'll be able to do some touch-up work on the trailer while the Gluvit sets up.

Good - I started to think, very dangerous - I know, that you were going to apply on the outside.

Are any rivets loose in the dripping video area? The bottom of the hull is one piece and when it was formed the bow section is folded up and the seam is behind the bow plate. That's why all the SC's have a pile of factory goop over that bow seam/crevice.