How difficult would it be to go electric?

I switched from hydraulic surge drum brakes to totally electric, self adjusting drum brakes. It was not hard to do. I was tired of the constant banging whenever I came to a stop and then accelerated from a stop. Plus the system was not working most if the time and needed constant repairs such as replacing slave cylinders, bleeding the lines, etc. I was just tired of it all.

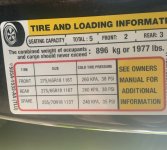

My truck also has the factory integrated brake controller.

My brakes are drums, so I'm not sure how much harder discs would be to do or how that will affect the price of parts.

I was able to use my existing drums with the new brakes, which saved some money.

I bought completely assembled self adjusting electric drum brakes that were mounted on new back plates, so it was an easy 4 bolt swap for each side.

Also keep in mind that electric brakes will require you to add an electric breakaway device in case your trailer separates from the tow vehicle.

Considering the condition of your trailer wiring, I would get a new wiring kit including LED lights. No more changing bulbs with the LED lights.

If you intend on going with electric brakes, you'll need the 7 pin round connector to accommodate the extra wires needed for the brakes.

I love my electric brakes. No more messy brake fluid or bleeding to do.

Plus with the factory brake controller, my truck integrates the trailer with the braking system of the truck. It reports if there's a problem with the trailer connection. It also responds accordingly to emergency braking situations, so it's not just a simple brakes on or off according to what your foot does. The computer monitors the trailer brakes.