Baylinerchuck

Commander

- Joined

- Jul 29, 2016

- Messages

- 2,726

I had a 16' Bayliner Capri and the max hp was a 90. It was a pretty quick little boat with that 90.

Special Delivery!

Special Delivery! I was told one Quart will paint my whole 16' boat!? I don't think this is possible!? Any estimates on what I SHOULD have for when the time comes?

I was told one Quart will paint my whole 16' boat!? I don't think this is possible!? Any estimates on what I SHOULD have for when the time comes? Here is the front Port Side Corner of the bow that had some damage and repair done. I bought Marine tex to repair the chips and cracks but I might have to do some research on fixing larger things like this! Any help is welcome!

Here is the front Port Side Corner of the bow that had some damage and repair done. I bought Marine tex to repair the chips and cracks but I might have to do some research on fixing larger things like this! Any help is welcome! Another Picture of the damaged area.

Another Picture of the damaged area. And One More.

And One More. Pencil Eraser Size hole Port Side as well, what would be considered behind the windshield.

Pencil Eraser Size hole Port Side as well, what would be considered behind the windshield. Also Some cracks along the top of the cap Port side as well. Looks like cracking from being old and dried out? I will dremel out all the cracks/chips and holes, then fill them back in as well.

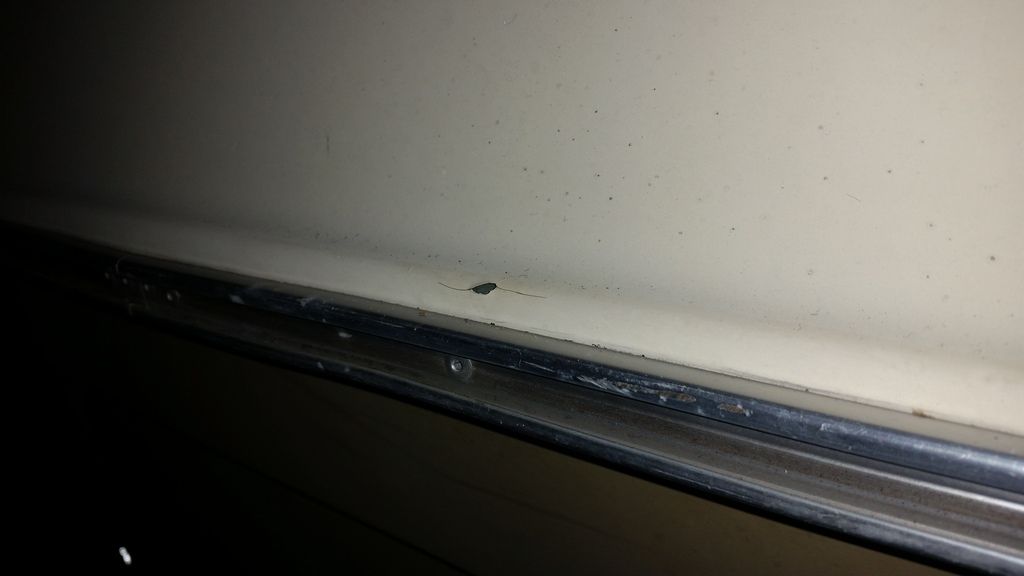

Also Some cracks along the top of the cap Port side as well. Looks like cracking from being old and dried out? I will dremel out all the cracks/chips and holes, then fill them back in as well.  Rear Port Side with the rubber removed out of the rub rail.

Rear Port Side with the rubber removed out of the rub rail. Port Side with the metal portion of the rub rail removed and rivets drilled out.

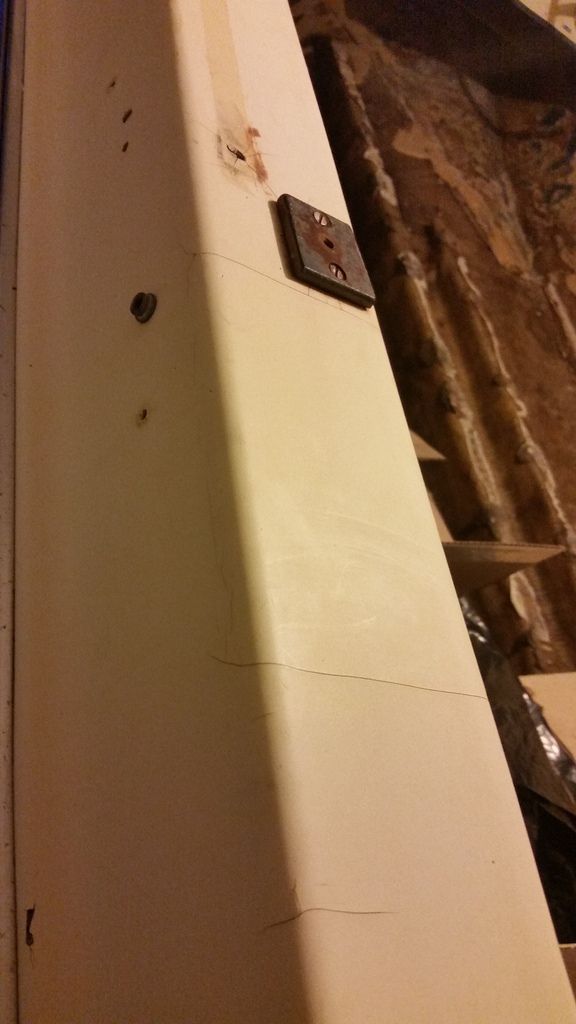

Port Side with the metal portion of the rub rail removed and rivets drilled out. Straight up the Stringer that would be under the captains seat.

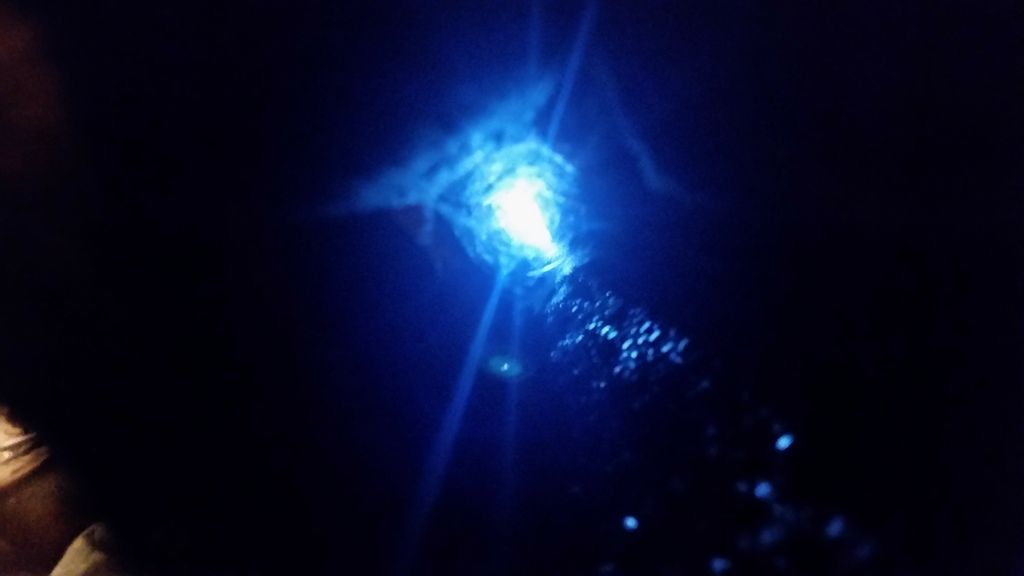

Straight up the Stringer that would be under the captains seat. I put a flash light at the other end to see if there were large chunks of wood or anything, but nothing...

I put a flash light at the other end to see if there were large chunks of wood or anything, but nothing...It's been a while but I pretty sure I did the white on mine with <2 quarts and the blue with <1. http://i176.photobucket.com/albums/w200/ezmobee/New Boat/DSCF2279.jpg

I applied it with a foam roller. Laid it on firmly with the roller spreading the paint out in a small section then rolling very lightly over top of that area to knock the bubbles down. Worked well and came out looking showroom. Perhaps Woodonglass will comment on whether he'd recommend adding the hardener to that marine Rustoleum.

You have any thoughts on the stringers??

I'm a tin boat guy so my advice is always going to be drag that boat to the dump and get yourself an aluminum hull LOL!

That being said, I have seen boats restored on here that had hollow stringers. In the 60's and 70's builders seem to have experimented with a number of different things for stringers. I've seen round ones where it looks like they glassed over cardboard tubes, hollow ones, foam filled ones and ones like yours where there's just like a wood strip to give screws something meaty-er to go into. The glass guys will tell you to grind them the whole way out and replace them with plywood and bed and glass those in. Honestly for that size boat anything that isn't going to rot further, adds rigidity to the hull holds the deck up sounds good to me.

First off, the TopSide paint is not needed. You're paying a premium price when the Rustoleum Pro will do just as well. If you can send it back I would! Rustoleum is NOT that good of paint unless you add the Acrylic Enamel Hardener. If you don't plan on using it, you WILL be dissappointed. Check the last link in my signature line below for painting info.

Hollow stringers need NO wood. The wood tops were added to aid with attaching the deck etc... IF they are still attached well to the hull and no delamination has occured I'd prolly just throw an layer of 1708 over em and call it good. You'll need to scuff sand em and clean well with acetone prior to laying the new glass.

Just make sure that the crack and delamination isn't due to swelling wood, a result of failed stringers.

This is the stringer to the left (Port Side) of the main that runs down the keel (the bubble is closest to the keel)

This is the stringer to the left (Port Side) of the main that runs down the keel (the bubble is closest to the keel) Same Stringer

Same Stringer Starboard Side of the main keel Stringer.

Starboard Side of the main keel Stringer. Birds eye of the previous picture location

Birds eye of the previous picture location Same just a little different perspective

Same just a little different perspective Main Keel Stinger....... Notice Crack Along Left Top Corner and Top Right corner slight behind.

Main Keel Stinger....... Notice Crack Along Left Top Corner and Top Right corner slight behind. Birds eye view of that section. Its location would be directly between the captains chair and the chair on the port side. Is almost dead center there.

Birds eye view of that section. Its location would be directly between the captains chair and the chair on the port side. Is almost dead center there.With the hollow stringers I would do as WOG stated earlier .... A good grinder cleanup acetone bath with a layer of 1708 mat side down ... Maybe 2 layers at the bad spots and call it good .

You may want to make sure you have good wood at the location of anything you want to fasten down to the deck like seats or something ...

Yep I agree. Forgot you stated they were hollow. They actually look really good!! That drill bit is something else. Must have been a cheap drill bit. Doesn't look like it was hardened at all!!