Foaming would be easier but my original tank was foamed in place and it captured a lot of water over the years. There was a lot of corrosion under the foam and rotted stringers. Plus, here are a couple of concerns from the Coast Guard regs:

From 33 CFR 183.550

(a) Each

fuel tank must not be integral with any

boat structure or mounted on an engine.

(d) Water must drain from the top surface of each metallic

fuel tank when the

boat is in its

static floating position.

(e) Each

fuel tank support, chock, or strap that is not integral with a metallic

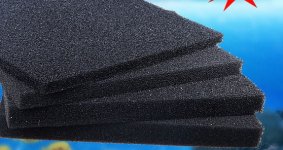

fuel tank must be insulated from the tank surface by a non-moisture absorbing material.

Foam around the sides even if the top is not foamed would trap water on top of the tank. All foam has a tendency to absorb water over time and would trap it next to the tank. Additionally, foaming the tank in place voids the tank warranty.