kcassells

Fleet Admiral

- Joined

- Oct 16, 2012

- Messages

- 8,741

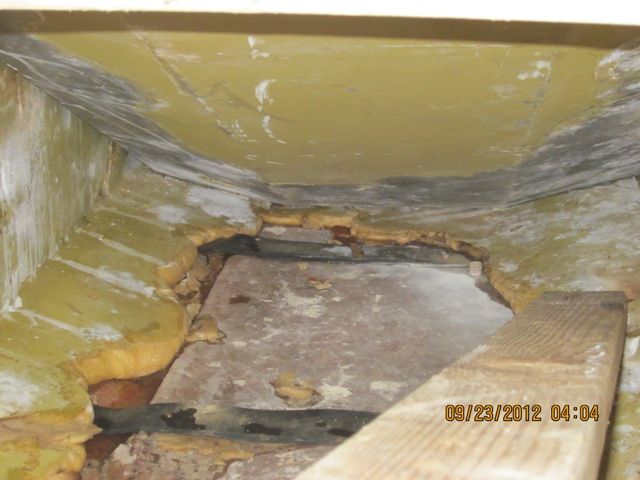

Mine also has the ribs. I'm putting the wedges at the edges, mainly on the back side due to I'm unable to get to the other areas. I tried some 1x4 and they went in but not very far with blunt ends, will put some 45's on them. Only had 2 beers and it looks like it will take at least 4, will try again tomorrow. Thanks

If you look at my prior pics you will see...definitely required 6! Good luck.. you'll beat her out just fine.