Re: First attempt at boat repair

Now to your heights & thickness Q's:

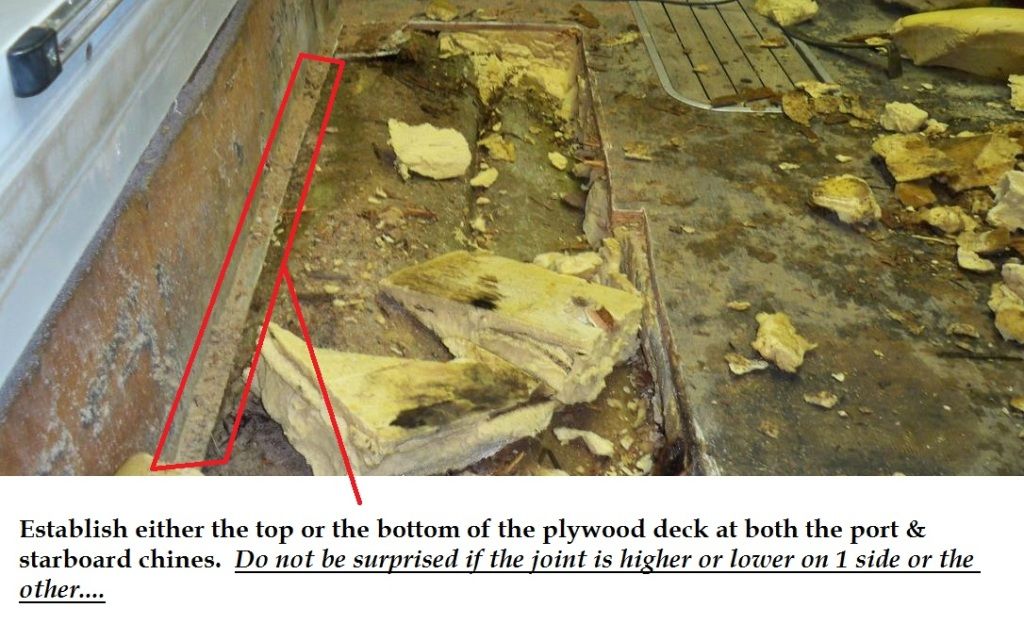

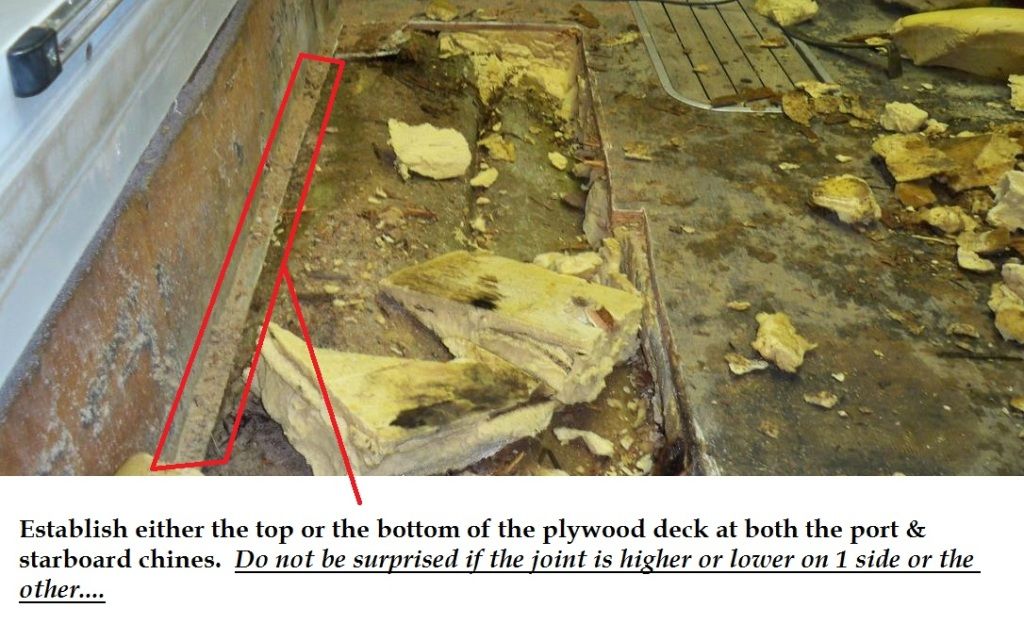

Using this photo of your hull:

You'll want to do your best to level the boat in your cradle as best you can. A long level or a nice straight edge across the transom and another location across the gunwales toward the bow. Boat building is unfortunately not nearly as accurate or as precise as piano building. Do not be surprised if you need to step back & make it 'appear' straight & level by eye. It will need to appear correct, whether the port & starboard gunwales & hull/deck joint actually are or not. With time & use, fiberglass does tend to sag some, particularly heavily constructed gunwales, consoles & decks that support super-structure above like a large roof & windshield assembly on a cuddy cabin or cabin cruiser. I didn't bookmark the thread, but somewhere around here someone rebuilding a Sleekcraft had almost a 1" deflection in a 6" wide gunwale surrounding the cabin roof & consoles on a 26' Sleekcraft Ambassador (may not be wholly accurate, but generally a large boat w/ a cabin that sagged). You will need to find a balance between level, straight & appearing correct....

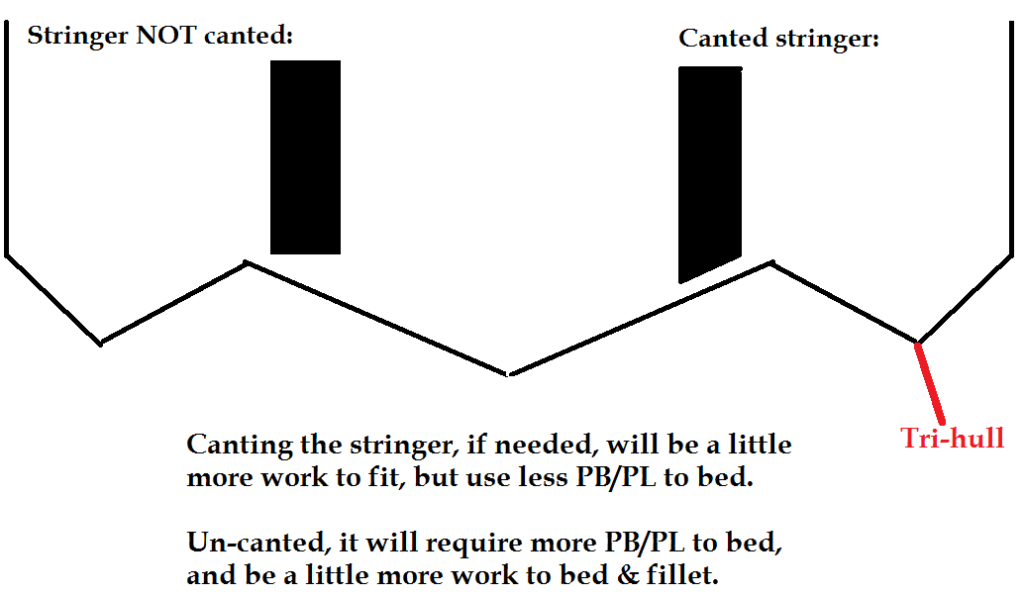

From the bottom of the plywood deck at the port hull, pull strings across to the starboard side in several locations... If there is drastic changes in the elevation heights from the string down to the hull, or lots of hull contours, more strings will give you more points & a much closer initial test fit. Measure down as square & perpendicular to the a cross the hull string lines as possible, at about what you think should be the centerline of the stringer. If the hull cants at the measured location, the stringer can, but doesn't need to, also cant. It will be bedded in PB or PL, a canted (beveled) edge will be harder to glass & harder to keep 1/4" off the hull prior to bedding. This is the MAXIMUM stringer height at any 1 location. From this #, you need to subtract 1/4" for spacing the stringer off the hull & bedding it in the PB or PL, this is your stringer height at each location.

Since you will be adhering the deck to the stringers w/ PB or PL and mechanically screwing or weighting the deck until the PB/PL cures, I'd suggest using 1 layer of CSM on both the top & bottom edges of the stringers, and 1 layer of CSM on the down side of your deck. I'd use 3/32" as my thickness per layer of CSM, so 1 on each surface is a total of 9/32". Allow an extra 1/32" to make it an easier # to work with: 10/32". Take this 5/16" from your stringer height (from above, already 1/4" reduced dimension).

So your from the original height at each location, your plywood stringers have been reduced by 9/16". For the PB & PL to adhere the deck down, let's add another 1/16", so our final stringer height at each location needs to be reduced by 5/8" +/-...

Does that ^^^ all make sense?

By using the bottom of the original plywood deck height at the chine, it doesn't matter if the factory did or didn't bed the stringers, did or didn't CSM the down side of the deck, and doesn't matter if they did or didn't CSM the top or the bottom of the stringers. You are pulling elevations off of the existing hull, and making allowances for how you'll put the stringers & deck back together. This also assumes you are able to tell what thickness plywood was used originally on the deck so you can replace it with the same. If you think the original deck thickness was insufficient, and want to use 5/8" or 3/4" instead of the likely 1/2" original deck, start at the TOP of the plywood deck at the chine, and deduct the thickness of whatever plywood you intend on subbing for the original when you measure the heights & start deducting for build up. Then your strings will need to be pulled across from the top edge of the deck at the chine.....

This gives you a flat, straight deck from port to starboard. Many manufacturers (Glastron did on my 1960 FireFlite) cant the deck towards the gunwales (the center is high) and have slight channels/coves at the deck/hull joint to direct the water rearward, but not into a bilge. Just out thru the deck drain hole in the transom. Mine is not quite an 1/8" higher along the centerline of the boat. If you want to cant the deck towards the center of the boat, where it will likely find it's way into the ski locker, make sure to plan to direct the water away once it's in the ski locker. Much more then a 1/8" cant, and you'll likely find that the cant will make fitting the consoles and seat boxes more complicated, and may even be noticeable when moving about the interior of the boat.

Hope that ^^ in both posts make sense.......