Red Herring

Chief Petty Officer

- Joined

- Oct 1, 2012

- Messages

- 536

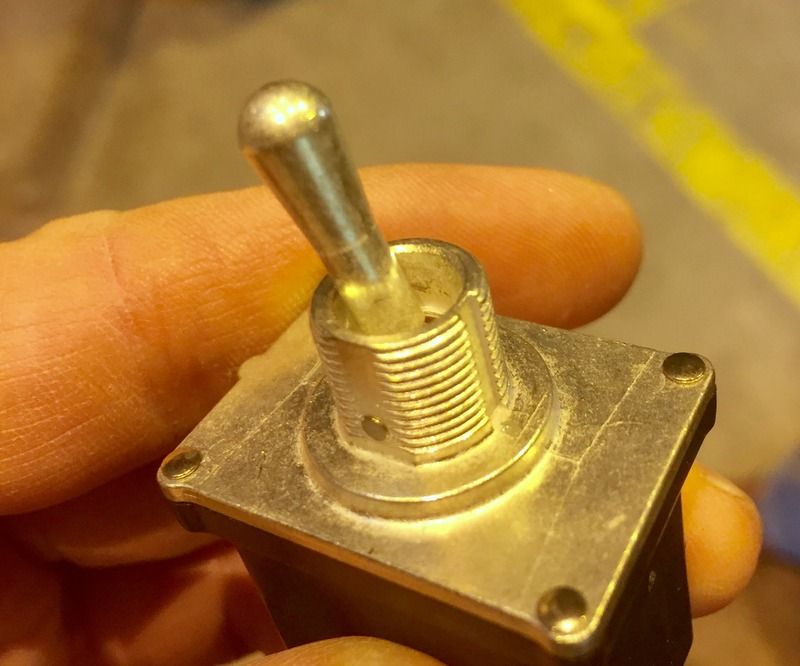

Ahh. Now I get it, those mounting holes! There's so much info in those datasheets that I totally missed that detail. I'll let you know when I get them.

Hmm, now that I can see the engine panel clearly I'm thinking if the switch panel border should be omitted to make them look more like siblings.

I really like that outer border though. Not a big issue at all and I'm very happy these are the current problems(no need to change anything Gm, just musing around, what do you guys think?).

Ok thanks!

The Bmw one is 3mm powdercoated/painted aluminium sheet, and I guess that they'll need to do it in 2 passes as you described to get the outer edges black (holes, corner shapes and screw countersinks first. Then paint and finally engraving?).