Thanks for all the great suggestions. Here is some trivia you all may want to know. I bought the boat 3 years ago but was not able to get to it until now. To my total dismay I have never seen anything in such disrepair, abuse and neglect. The boat itself looked promising, needing some TLC, of course, but when I started in June trying to get it seaworthy I was in for a shock. If this boat had been a child, child protection services would have been called in to action. The engine and/or outdrive is locked, so there is no chance for me to turn anything. Once I get them separated I will see which is locked, if not both. The engine is a pile of rust, at least externally, the alternator is frozen and my first thought was, yank the engine and haul it to the recycling center. But this is not my nature. Admitting defeat and capitulation is not part of my world and I get more stubborn than a pit-bull when challenged. Now I am determined to restore this boat to a presentable state. I wouldn't be surprised if this boat has not been in the water for 10-15 years, that the bilge was flooded at least once at one time. I admit I didn't look close enough when I bought it and now I have to deal with it and I will, one step at a time. Once I get the engine out of the boat I will take it apart and see what the problem is and determine if it can be salvaged, the same goes for the outdrive. As you all know, my problem right now is, both rear motor mounts are frozen solid and the outdrive is stuck in the gimbal housing like it was all one piece and a Budweiser Clydesdale couldn't pull it out. I am working on a number of ideas incorporating all of your suggestions and eventually these obstacles will be overcome, always has in the past. I'll keep you all posted. The good news is that the boat itself appears to be solid and in decent shape. No rot in the transom or other areas that I can see so far but I won't hold my breath.

What I have done so far:

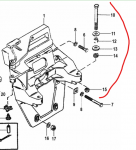

I was able to get to the grease nipple on the coupler and pumped about half of the gun's grease in to the coupler. I hooked the engine to an engine hoist and lifted it about a 1/4" up so I could jerk it around a little hoping that the alpha one would break loose while the outdrive was subjected to tremendous pull. I used the wedge trick (piece of wood between upper unit and transom) but could not use the trim hydraulics because there is no power. And it probably wouldn't have done any good anyway. So I used a nearby tree, attached the outdrive to it with a ratchet and gave it as much tension as I thought I could afford without causing damage somewhere (pictures). The outdrive needs to come out. That is the next move. Until that happens all has come to a screeching halt. Any other suggestions and tricks are more than welcome. Excuse this novel here, but I felt I needed to explain a little more in detail.