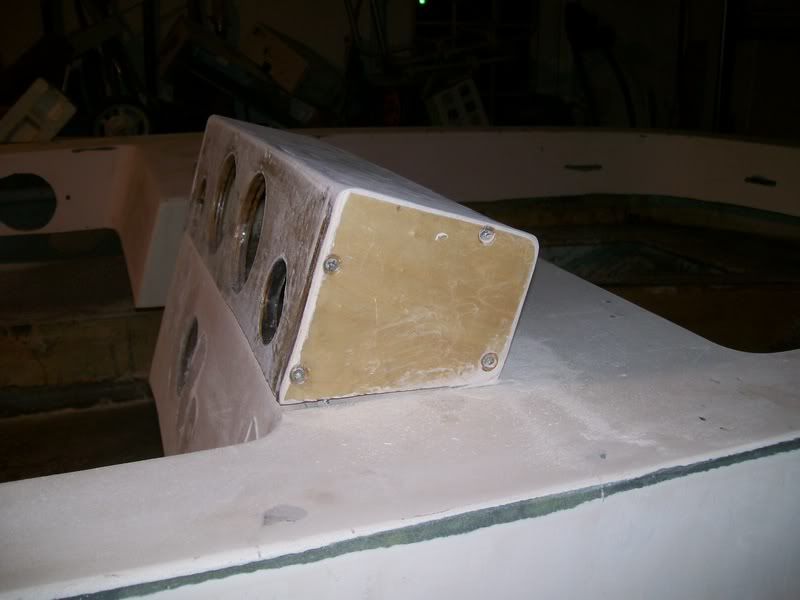

Re: Ebbtide Tri-Hull Restoration

the restoration is looking great !

what kind of fiber glass did you use to bond both 3/4 pieces of transom wood ? I heard of some people using some kind of mixture of catalyst and a fiber I can't recall at the moment to laminate the transom wood together. also is what you used to make the transom and outer skin bond the same materials ? I am rebuilding a boat also and its my first time.

I just went old school on it. Bonded it with polyester resin and fiberglass mat. When you mention catalyst. Normally all resins utilize some type of catalyst to create the chemical reaction that hardens the resin. Polyester uses a Methyl Ethyl Ketone catalyst at approx 12 drops of catalyst to an ounce of resin, while Epoxy resins use a quantity of 1:2 catalyst:resin. The difference between the two is that with polyester the amount of catalyst used determines the gel time, and with epoxy you use the catalyst type you need slow-medium-fast cure and put in the same amount.

If you are going to do this, make sure you have everything ready before you add the catalyst to the resin. And I mean everything.

STOP: Did you do a gel test on your resin to see how long it takes to cure. If not, waste one or two ounces. You'll thank yourself later.

1. Make sure your mat is cut and ready to apply.

2. Make sure your clamps are out and ready to put on.

3. SS Screws at hand

4. Power Drill plugged in and ready to go.

5. Paint Brushes/Rollers/Fiberglass rollers at hand.

6. Acetone wash and rinse containers filled and ready to be used (for your tools)

7. Nitrile gloves (get a whole box) near your work area. I use 5-6 pairs everytime I bust out the resin. Maybe I'm a slob, but laying up fiberglass makes a huge mess.

Nothing is worse than when you have a pot of catalyzed resin sitting while you're searching thru 4 different tool boxes looking for your #2 Phillips screwdriver bit. Don't ask me how I know this.

I debated using epoxy resin, but with all of the fiberglassing I have to do on this project (~6-7 gallons of resin needed) I just couldn't swing $500-$600 on resin alone.

Other considerations for using polyester are that this boat when finished will be strictly a trailered boat that will be garage kept when it is not at the lake.