Speaking of the molds . . .

I have been ordering supplies and will be going to a fiberglass supply shop tomorrow (Friday) to pick up the bulk of the glass and resin.

My shopping list looks something like this . . .

Mold Release Wax

PVA

Mold Release wedges

Tooling gelcoat (gallon)

5 Gals tooling resin

20 yds 1.5 oz CSM 50"

10 yds 24 oz Woven Roving 38"

16 yds DBM1708 50"

6 gals VE resin

5 ea of 2'x4' Urethane foam boards 4.5 lb density, 1/2" thick ( aka "Last-a-Foam" )

Peel ply

Breather mesh

1/2" pvc tubing 100'

plastic T fittings

spiral wire wrap material 60'

I still need to get the hardware for the mounting and other fittings.

Budget-wise I am looking at about

Plug $250

Mold $400

Platform $750

Hardware/fittings $600

Total $ 2,000 ish

I did a lot of searching for a suitable and inexpensive core material, and finally found "Last-a-Foam" 1/2" thich at about $3.50/ sq. ft., which was about half of other materials, such as Divinycell.

Also, I am considering doing away with the struts, since Formula does not use them on their platforms, and this platform will have a bit more 'depth' for structural support than the Formula design.

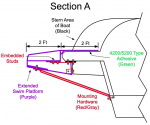

I have also simplified the underneath design, based on information that I got from Formula Tech Assistance Group (TAG). Here is the latest on the design.