Quick Update:

I posted some pictures of my swim platform on the 'boat design net' forum for comment. Nothing earth shattering so far, but several comments/questions on how I plan to attach the platform to the boat. It seems like that is a concern :noidea: . . . It got me thinking more specifically on how I plan to do it, which I should share.

So, I plan on using some pretty beefy stainless steel 'L' brackets. 4 underneath and 2 on the sides. The slab portion that goes over the existing swim deck will be secured with adhesive. The outer edges will have the struts, along with the center strut.

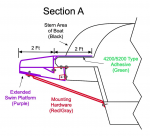

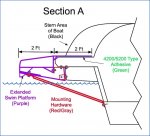

Here are some drawings on the current plan . . .

Here is an overhead view showing the stern area in black, the extended platform in purple dotted lines, the adhesive areas in green, and the hardware in red. I left out the center strut in this diagram, but it will be trough-bolted at the platform and lag bolted at the transom.

Here is a cross-section side view, showing the details of the 'L' brackets and bolts. Probably 1/2" SS bolts. . .

What say the group? Sufficient? I'm not sure where else/how else I can secure things . . . Thoughts? Comments?