Cruisers still need the support of stringers and bulkheads, but the accommodation of living space below deck means that the designs are a bit different. . . . Usually there are as many if not more stringers since often they cannot be as tall as those of smaller boats. The height of the boat provides some rigidity for cruisers, but cruisers are pretty flimsy compared to a deep V center console.

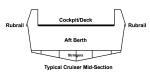

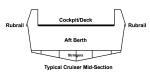

Here is my handy work diagramming what you are seeing with the mid-section of the Crownie 250

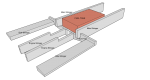

The stringers typically support the cabin floor and the sleeping berths, The cockpit deck acts as the roof of the aft cabin and is generally supported by the entire cockpit liner, which is attached at the rubrail, and by a bulkhead or two.

I typically use EG in isolated areas where moisture/rot is just starting into an otherwise good section of wood. It is certainly a judgement call as to using EG versus cutting and replacing. Keep in mind that a common theme to all of the restorations/repairs is that they start out having a perceived scope, being somewhat limited and manageable. Once you start opening things up the extent of the problems usually goes 3X of what you had planned.

I know on my Formula, I initially figured that I could cut out the main bulkhead, replace the center section of it and be done. Then I saw the issue with the fuel tank. Once I removed the fuel tank for repairs, I saw that the storage compartment floor in the mid-section of the boat was wet and rotting. so, the scope of the repairs went 3X on me.

You need to be prepared that once you start the repair process on your boat, you will find more issues than you were hoping. The thing to do is to do it once by doing it right.

Anyway, if the bulkhead is rotted and the rot has spread into the center-most stringers that support the engines, I suspect that the rot has also progressed forward into the stringers that run underneath or alongside the fuel tank and under the aft berth. You noticed that BigDirty took the interior out of his Crownie 250 to be able to get at everything. He found a greater extent of issues as he went, bringing him all the way forward to the main cabin. Hopefully your boat will not need that much work, but it is important to know the extent of work it needs.

You can probably seacast the engine mounts.

I would not cover a rotted stringer with additional fiberglass. Rather remove the rot and rebuild the stringer and glass it accordingly. You can use plywood as most do to rebuild things, but you can certainly use other materials like foam or some of the synthetic boards.

If a structural member or area is just starting to see moisture or rot, then you can use EG on those parts . . . dry it out really good and glass that area.

Anyway, I hope that helps. I am heading to the West Palm Beach area, but will only be there for a day or 2. Possibly, I could take a look at your boat.