Wow, I am impressed pal! I'm working on getting a trailer/haul. Do you think 3 stacks of blocks and 6 stands are adequate support the hull while performing surgery on the boat?

You are welcome . . . sorry that I can't come see the boat today, but the drawings that Sea Ray sent, plus the pictures you posted are the next best thing to being there. I *think* this would be the way to approach the repair . . .

Here is your boat's structure . . .

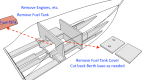

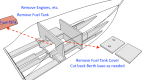

I would . . .remove the outdrives, engines, etc.

Remove the panel covering the fuel tank.

Remove the fuel tank . . .

This will then give you an 'inside' view of the bulkhead and the main stringers so you can verify the extend of the damage.

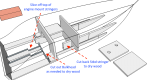

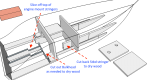

You may have to cut out part of the aft berth base on the starboard side to expose the starboard stringer more thoroughly. This will be more repairable and I don't think you will have to remove the aft berth bulkheads. You probably will need to cover the vinyl wall upholstery, etc. with plastic drop cloth.

You should then be able to remove the culprit bulkhead and cut back the starboard stringer as needed.

You could also 'slice' the top of the engine mount stringers to expose the bad wood, clean them out and prep them for seacast filling. (Keep the tops that you cut off to re-apply them later)

Then, it is a matter of building things back the way that they were. You probably want to take lots of measurements before you do the demolition so that you can reference them as you re-build.

Anyway, that's how I would envision it being done, but I'm sure there will be a few 'gotchas' along the way and other forum members will have ideas as well.

As far as support . . . 3 places (transom, bulkhead, bow) may be enough . . . 4 places along the keel would be better. 6 stands (3 each side) right under the chines should be fine. Just be sure to get everything set and secure before doing any demolition.