Scherfz1

Petty Officer 1st Class

- Joined

- Jun 4, 2019

- Messages

- 238

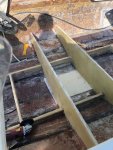

Yep I thought I would cut everything as close to square, level, etc. Ya nope. Never fit right. Up and down the ladder to trim this or sand that to get it to fit CLOSE. That’s what PB is for. Fill the little gaps that never match perfect. Doing some great progress. Show some more pics.

ya man up and down is getting old lol, but oh well its all apart of it. and i will get pics, its been too long, but with the rain yesterday and rushing to get the glass work in the garage, i said screw it.

on a further note, i am no longer allowed to keep wet glass in the garage. GF lost her mind when she came home to a resin smelling house that has finally died off to an extent this morning, its still slightly lingering, but hell i had negative pressure on the garage and it did nothing for it....